Asset tracking is changing rapidly under the influence of technologies such as the Internet of Things. RFID in one of them. In this article, we’ll tell you about RFID solutions and some of the use cases we’ve encountered in our practice as IoT developers.

RFID Asset Tracking Solutions: Software and Hardware Work Together

RFID, or radio-frequency identification, is a technology that allows you to track objects automatically using radio waves. The global RFID market is rapidly growing and is expected to reach $13 Billion in 2022.

RFID systems consist of two main components: reader and transponder.

A reader, or interrogator, is a network-connected mobile or fixed device that transmits and receives radio waves to collect data from a transponder. A transponder (often referred to as an RFID tag) is a technology that collects data and sends it to a reader. A tag consists of an integrated circuit (a chip) and an antenna for receiving and transmitting radio signals. RFID tags can be powered by batteries or directly by a reader.

An RFID asset tracking solution consists of two interconnected parts:

- Hardware – devices in various forms. For example, a card with an RFID chip and a scanner for such cards. The hardware part exists to collect and transmit data;

- Software – a digital system that processes data received from hardware. The software part provides you with analytics, visualizations, and reports.

So what is the role of RFID solutions in a company’s asset tracking system? They automate identifying and tracking assets such as vehicles, equipment, goods, and more. Automation measures reduce operational costs and mitigate behavior-related risks. Generally, RFID systems are used together with GPS and QR codes. In many cases, these technologies are accompanied by IoT sensors to improve control even further.

How Does RFID Asset Tracking Software Help with Visualization & Reporting?

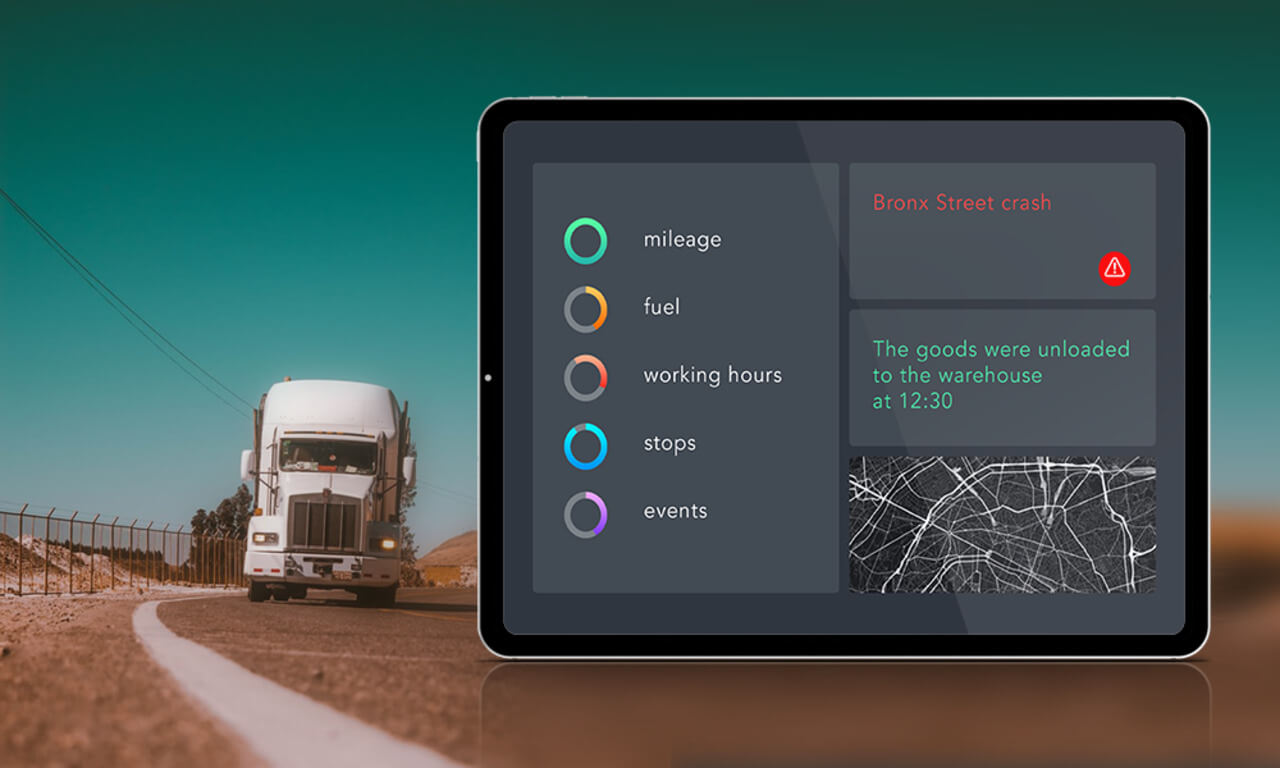

RFID asset tracking software visualizes collected data using three modules:

- 1. Real-time map;

- 2. Status and characteristics;

- 3. Reporting.

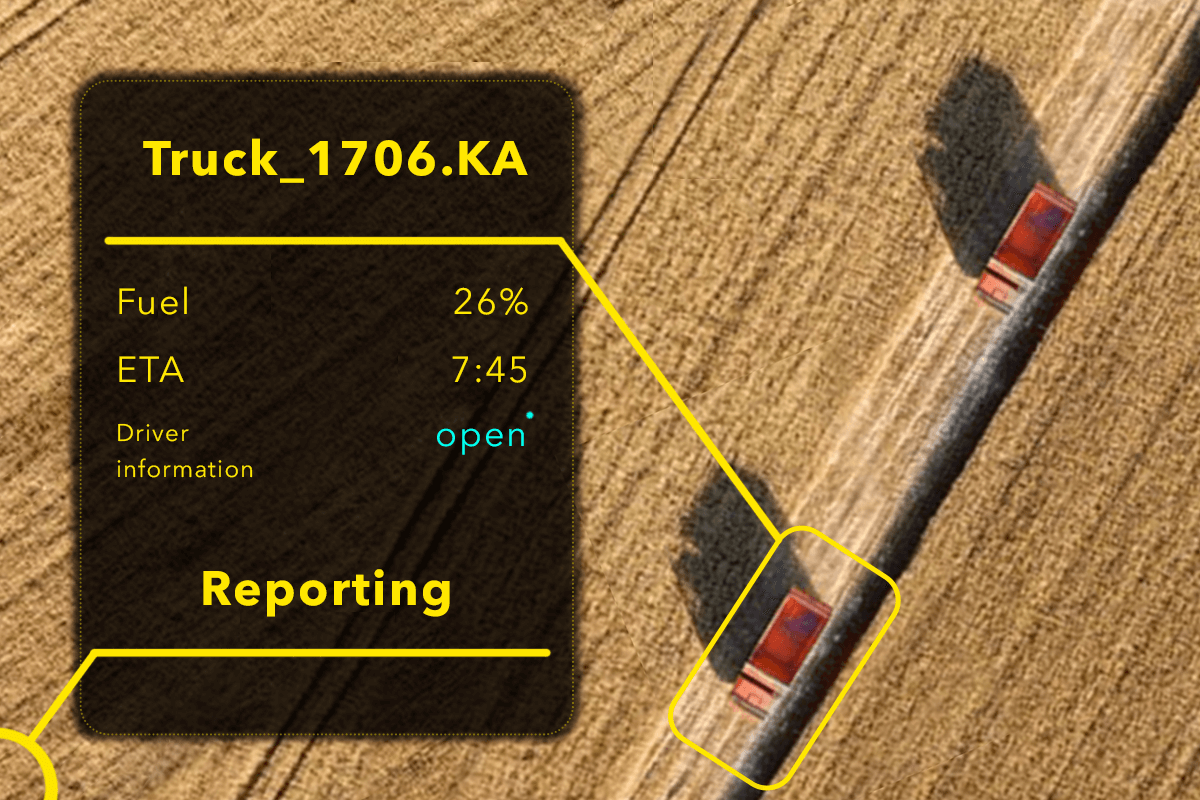

The first module, the Real-time map, shows your assets’ location. All assets are displayed, and any changes in the assets’ location will be reflected accordingly. Let’s say you’ve pre-determined a specific area for your vehicles to operate in. The map allows you to determine at a glance whether or not all units are within the area.

The Status and Characteristics module provides you with information about your assets and their state. Tracked characteristics depend on your needs and software customization. Let’s take fuel as an example. By analyzing the covered distance and fuel consumed by commercial vehicles, your software systems can show you malfunctions or deviations from the direction.

The Reporting module will provide you with a summary of what’s going on with your assets. The space for report configuration is vast. Let’s say that every morning at 09:00 a.m., you need a report on fuel consumed by your logistics fleet. Not a problem! In this case, tracking software will gather all data regarding fuel consumption by each vehicle, highlight potential issues, and send you a detailed report whenever you need it. Reports can be delivered in the form of your choice, including spreadsheets and PDF files. Alternatively, you can access reports with an Android or iOS app.

RFID Use Cases

The important thing to understand about RFID use cases is that they are not bound to one industry. The experience of using RFID asset management solutions in agriculture can easily be applied in retail. Same with other industries and use cases. With this in mind, let’s take a look at RFID asset tracking in logistics, agriculture, and the oil industry.

RFID in Logistics and Transportation

RFID solutions can automate supply chain management and reduce the negative impact of human behavior. So what is the role of RFID in logistics and transportation? RFID technologies help with the following:

- Fuel consumption control;

- Drivers’ working time control;

- Product monitoring;

- Transport identification.

Implementing RFID solutions helps to get better control over fuel consumption. RFID tags and tracking software will help you determine if your trucks use an optimal route to deliver goods. Moreover, RFID trackers help to detect downtime or abnormalities like fuel misuse. How?

Software systems collect information about the amount of fuel received by your employees and the total distance covered by your company’s vehicles. To improve the level of control even further, you can install sensors to monitor fuel levels. Apart from that, RFID will help you enforce your policies and prevent the unauthorized/excessive use of agricultural vehicles and fuel for personal needs.

RFID tags can be used to monitor the working hours of any employee. It is essential to monitor drivers’ working time in logistics, as a critical shortage caused a significant increase in their pay. Scanning cards with RFID tags at the beginning and the end of the day provides detailed info on working hours and downtime. Such data helps to control operational costs better.

Product monitoring with RFID helps you to automate your supply chain management significantly. The idea here is simple. Anything from a box of chocolates to a freight container can be equipped with RFID trackers. Such trackers can locate products automatically and identify delays. This helps a logistics team to automate reporting and decrease operational costs.

Transport identification, a.k.a. “Friend or Foe” systems help improve the security level without deploying more staff to the field. RFID trackers ensure that only authorized vehicles can access your warehouses, grain elevators, and other facilities to load and unload goods. Plus, you’ll likely need a detailed access log for business, security, or legal purposes.

Traditionally, companies assign employees to oversee access and prevent unauthorized movement of vehicles and goods. Alternatively, you can use RFID trackers, which are cost-effective and help avoid potential security breaches due to human error. Trackers and software systems will both prevent unauthorized access and provide an activity log as a report.

RFID in Agriculture

The use of RFID technology in agriculture has become routine. Here are some of the tasks that agricultural companies can automate:

- Control over land zones;

- Irrigation and treatment with plant protection products;

- Tracking of agricultural products;

- Fuel consumption control.

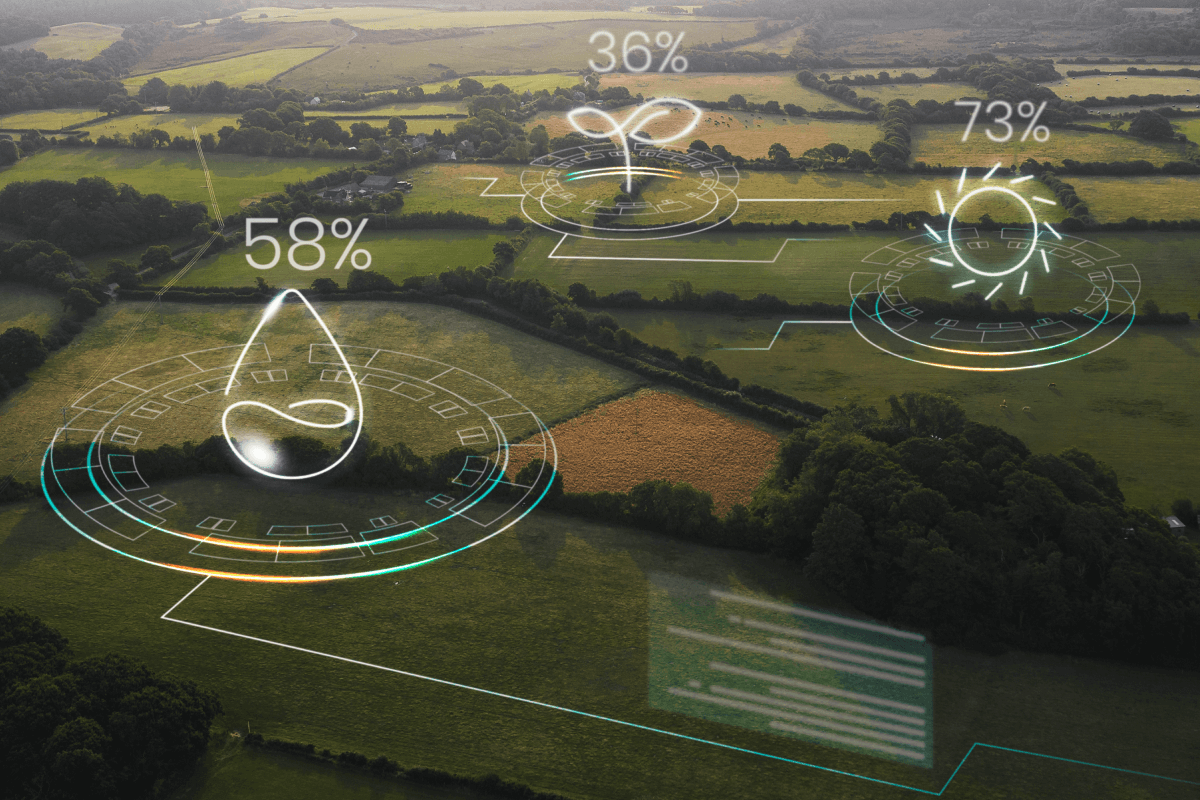

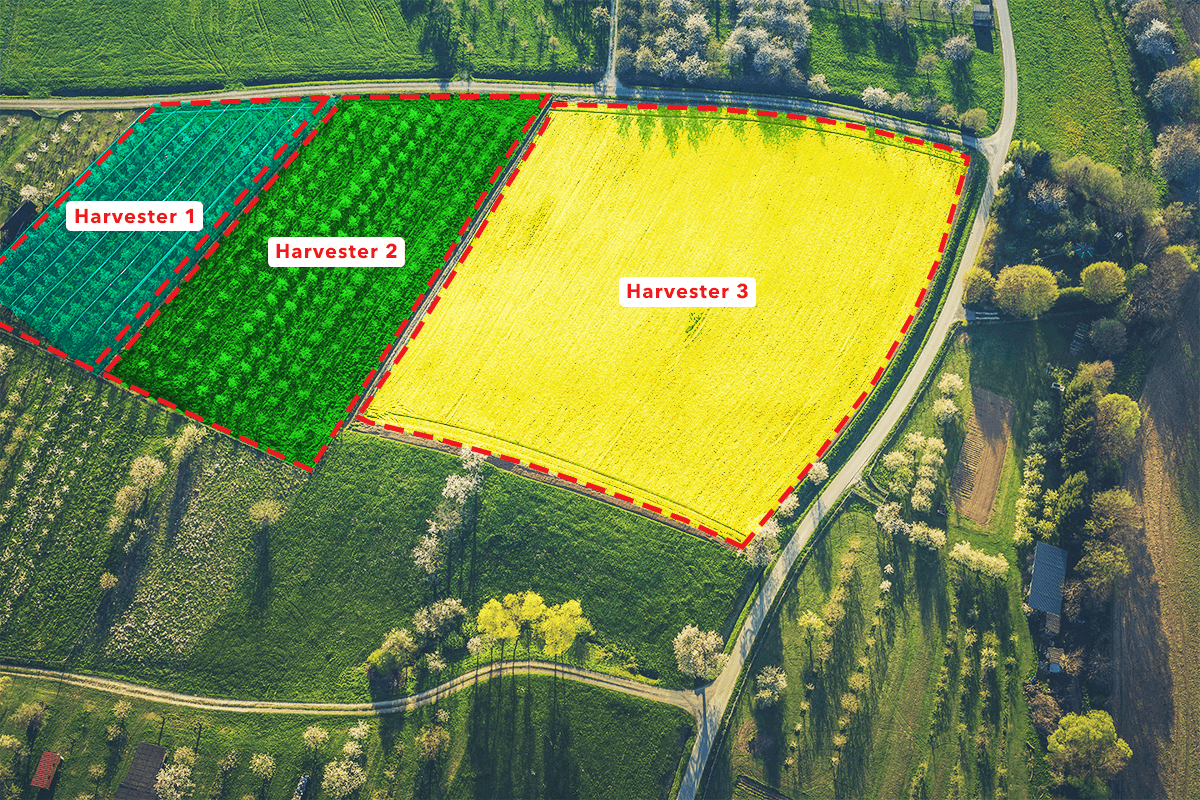

Usually, agricultural businesses have their lands divided into several zones: cultivated and non-cultivated land plots, no-till plots, etc. With RFID software, you can visualize such land zones and monitor their statuses. For example, you can get real-time information about the location of your harvesters and their work progress.

Moreover, RFID can be utilized in irrigation and treatment with plant protection products. How? RFID tags can serve as a component of complex IoT systems for agricultural automation. Such systems, equipped with various sensors, can analyze a field’s condition and determine the volume of required water/plant protection products. Special software will adjust the spraying systems (and even drones, if you use them) accordingly.

Same as with other goods, RFID tags help with the tracking of agricultural products. With such tags, you can oversee the movement of products through the whole supply chain. You’ll know when crops were harvested, which vehicle delivered them to a grain elevator, and so on. Such information helps optimize asset tracking and reduce the loss of products, both raw and processed.

Finally, let’s not forget about fuel consumption control. Fuel consumption control is crucial in agriculture, as distances in rural regions are high, and even a slight optimization of usage can save an enormous amount of fuel.

RFID for Industrial Equipment

Needless to say that RFID solutions can be used to oversee material supply and equipment transportation. However, the application of RFID technologies in manufacturing, mining, and similar industries is not limited to supply chain management.

Tags can be assigned to industrial equipment and machinery: cranes, platforms, forklifts, and so on. Often, RFID trackers are accompanied by IoT sensors to provide you with additional data regarding the status of your equipment. RFID solutions vary depending on the needs of a specific industry.

Let’s take the Oil & Gas industry as an example. Asset tracking with RFID, GPS, and QR codes is one of the most prominent trends in this industry. Here are the processes that asset tracking solutions improve:

- Equipment monitoring;

- Incident detection and reporting;

- Access tracking.

RFID solutions provide visibility over industrial equipment. You can track its current maintenance status and history. With the needs of the industry in mind, RFID tags are designed to endure environmental challenges such as extreme temperatures, vibration, and high pressure.

Sensors with RFID tags can provide data about the environment, including temperature, depth, velocity, and pressure. Such information helps to automate incident detection and reporting. For example, RFID tags with sensors can monitor the temperature of oil pipelines to prevent leaks.

Cards with RFID tags are used for access tracking. To monitor working hours, improve safety in harsh environments, and prevent unauthorized access to critical equipment. When an employee scans a card, the system receives this information and allows access.

Custom RFID Solutions Development

RFID technologies find their use across many industries. However, the implementation greatly depends on your company’s needs and workflow. Thus, the whole RFID solutions development process can be divided into four stages:

- Analyzing existing business processes to estimate costs and returns;

- Developing software systems that collect, store, and analyze data;

- Integrating software with RFID trackers;

- Implementing RFID solutions into your workflow.

Softengi, an expert company in IoT development, can help you with the end-to-end implementation of RFID and other asset-tracking solutions. Do you have more questions related to asset-tracking solutions development? Contact us now!