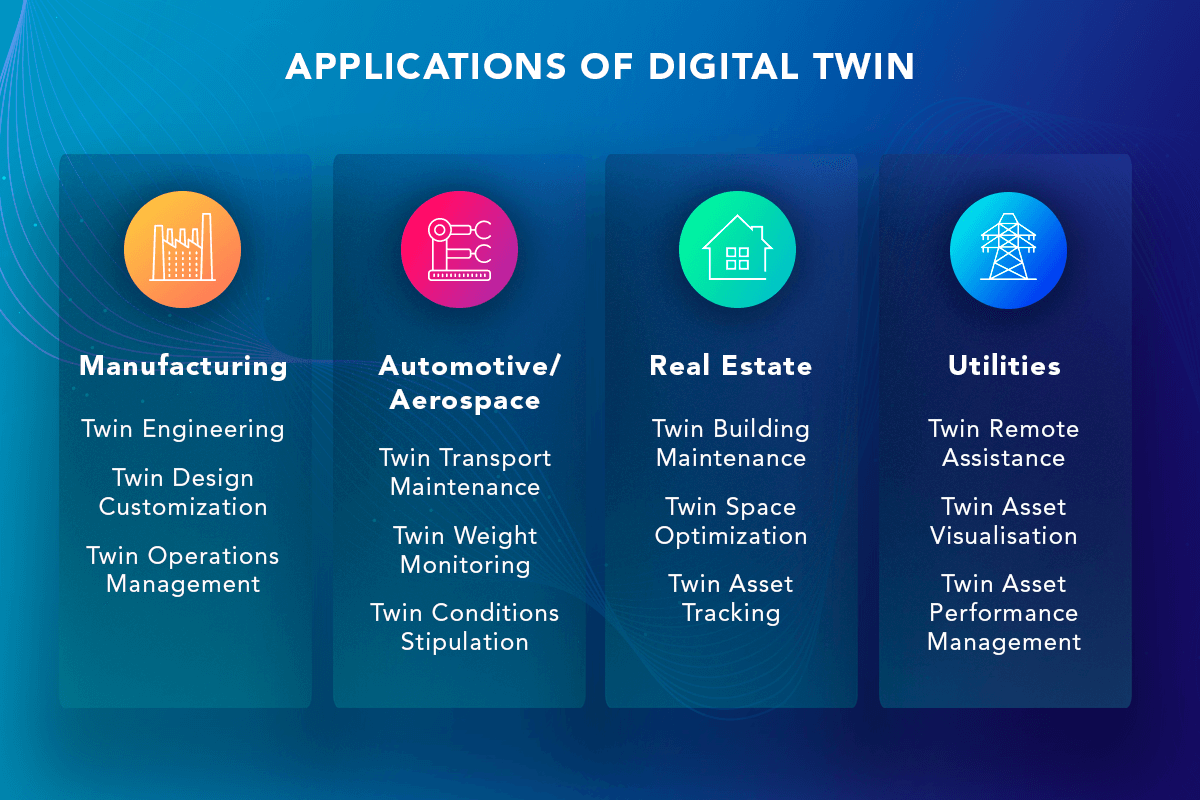

Today Digital Twin applications are widely used across many industries. Providing accurate virtual representations of objects and simulations of operational processes, applications of Digital Twin enable various businesses to promptly identify areas for innovation and improve business processes and performance. Among the digital twin examples are Product Digital Twin, Component Digital Twin, and Performance Digital Twin, all used to visualize objects and processes, be they single or more complex.

According to Gartner’s Survey, 75% of interviewed organizations that already work with IoT use the applications of Digital Twin.

Global Market Insight claims that the Digital Twin market size, estimated in 2018 at $3 billion, is expected to grow to $20 billion during the period from 2019 to 2025.

Digital Twin is a virtual replica of a real-world asset. A real-time digital representation of a physical item is achieved due to the constant data transmission, which allows the virtual object to exist simultaneously with the physical one.

How to Develop and Implement Digital Twins Into Your Company’s Business?

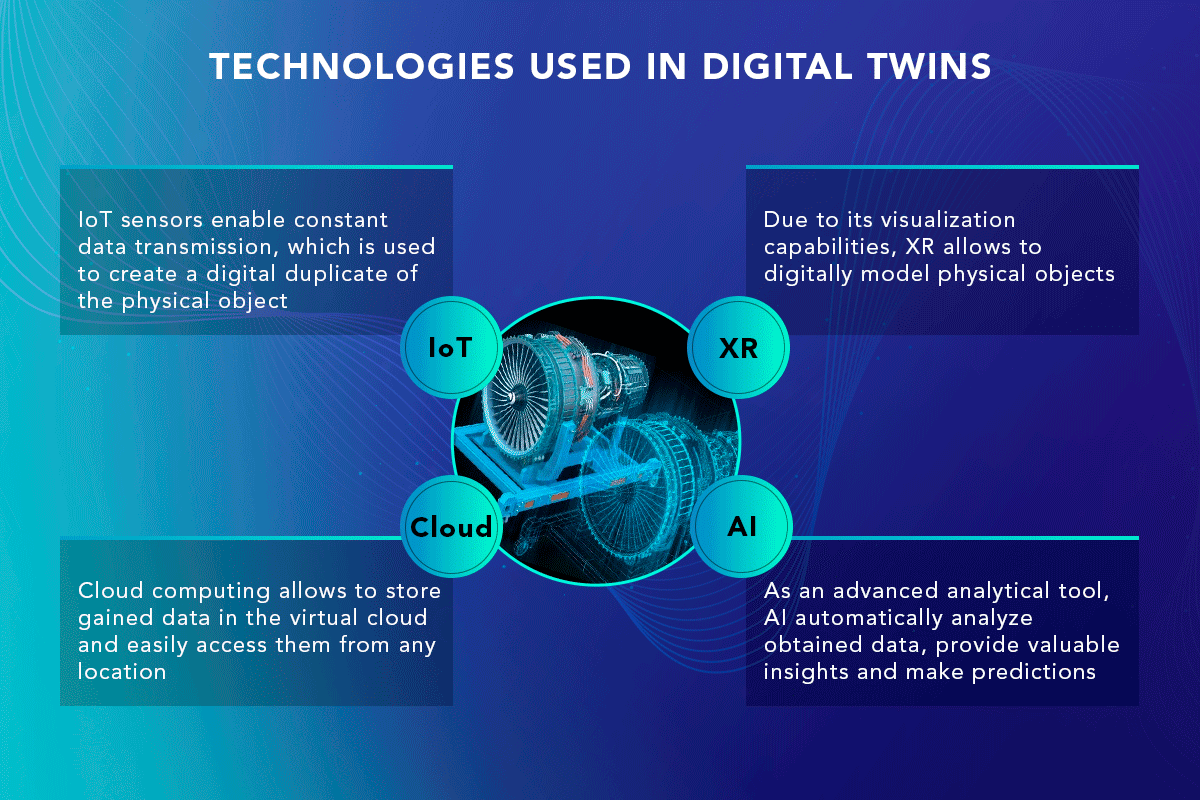

Technologies Used in Digital Twins

An application of Digital Twin embraces four technologies allowing to create a digital representation, gathering and store real-time data, and, based on the obtained information, providing valuable insights. Among Digital Twin technologies are the Internet of Things (IoT), Extended Reality (XR), Cloud, and Artificial Intelligence. Depending on the application type, a particular technology can be used to a greater or lesser extent.

- The Internet of Things (IoT) is the main technology used in every application of Digital Twin. IoT is based on collecting data acquired from real-world objects with the help of sensors. These data are then used to create a digital duplicate of the physical object that can be analyzed, manipulated, and optimized. Therefore, the value created by the IoT is governed by the flow of information through a system. IoT helps a Digital Twin application to connect a virtual representation with a physical object in real time, keeping it constantly updated.

McKinsey suggests that by 2025 the total potential economic impact of IoT technology will be growing from $3.9 trillion to $11.1 trillion a year.

- Extended Reality (XR) is the visualization technology that creates digital representations of objects. XR capabilities enable Digital Twins to digitally model physical objects, allowing users to interact with digital content;

- Cloud Computing technology is used for efficient storing and accessing data over the Internet. As applications of Digital Twins operate with large volumes of data, cloud computing allows to store all data in the virtual cloud and easily access the required information from any location;

- Artificial Intelligence (AI) is an advanced analytical tool that is able to analyze obtained data and provide valuable insights automatically. It can also make predictions about possible outcomes and give suggestions as to how to avoid potential problems.

Applications of Digital Twin in Manufacturing: Digital Twin for Engineering

Before developing a complex physical product, digital twin technology creates its virtual model that can be virtually tested and improved. With digital twins, companies can simulate and validate each development step to identify problems and possible failures before producing the final product. Twin Engineering helps development teams to understand how a potential change in the manufacturing process may impact production outcomes and adjust their manufacturing operations accordingly to achieve targeted improvements. As a result, manufacturers can enhance operational processes and therefore reduce the overall costs of engineering.

Digital Twin for Design Customization

As consumers are getting more sophisticated, tending to demand customized products in the short term, the manufacturing industry becomes increasingly competitive. According to IndustryWeek Special Research Report about the future of manufacturing, industrial companies of all sizes share a common focus on the improvement of production processes and strengthening customer relationships, while small companies concentrate their attention on meeting customer demand for product customization.

To facilitate the product customization process, manufacturers embrace Twin Design Customization, which allows to design and re-design items virtually before developing a physical product that fully complies with the consumer requirements.

Read more about Twin Design Customization in Manufacturing.

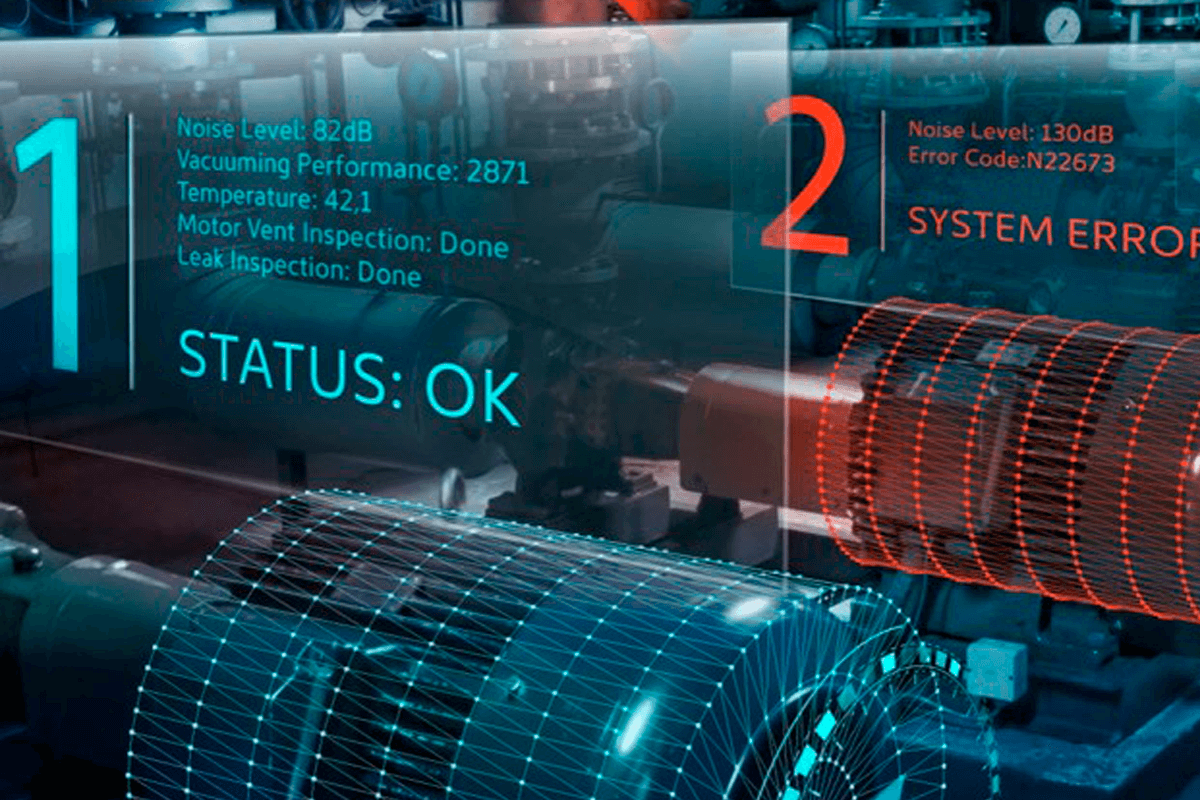

Digital Twin for Operations Management

Twin Operations Management enhances operational efficiency, predictive maintenance, and dynamic simulation. The real asset is embedded with IoT sensors that constantly transfer real-time dynamic data flow related to the asset and its condition. Then, based on static data and constantly updated dynamic information, the digital replica is built. Employees can virtually monitor and manage asset performance and manufacturing operations.

Digital Twin Use Case Example: Kaeser

Kaeser, one of the leading manufacturing companies and compressed air products providers, has applied digital twins that enable the company to switch from selling a product to selling a service. Digital Twin system constantly provides Kaeser with operational data on the equipment during its lifecycle, particularly – the air consumption rate. Such monitoring has allowed Kaeser to charge clients based on air consumption rather than at a fixed rate. As a result, the company has reduced commodity costs by 30% and onboarded nearly half of all major vendors using digital twins.

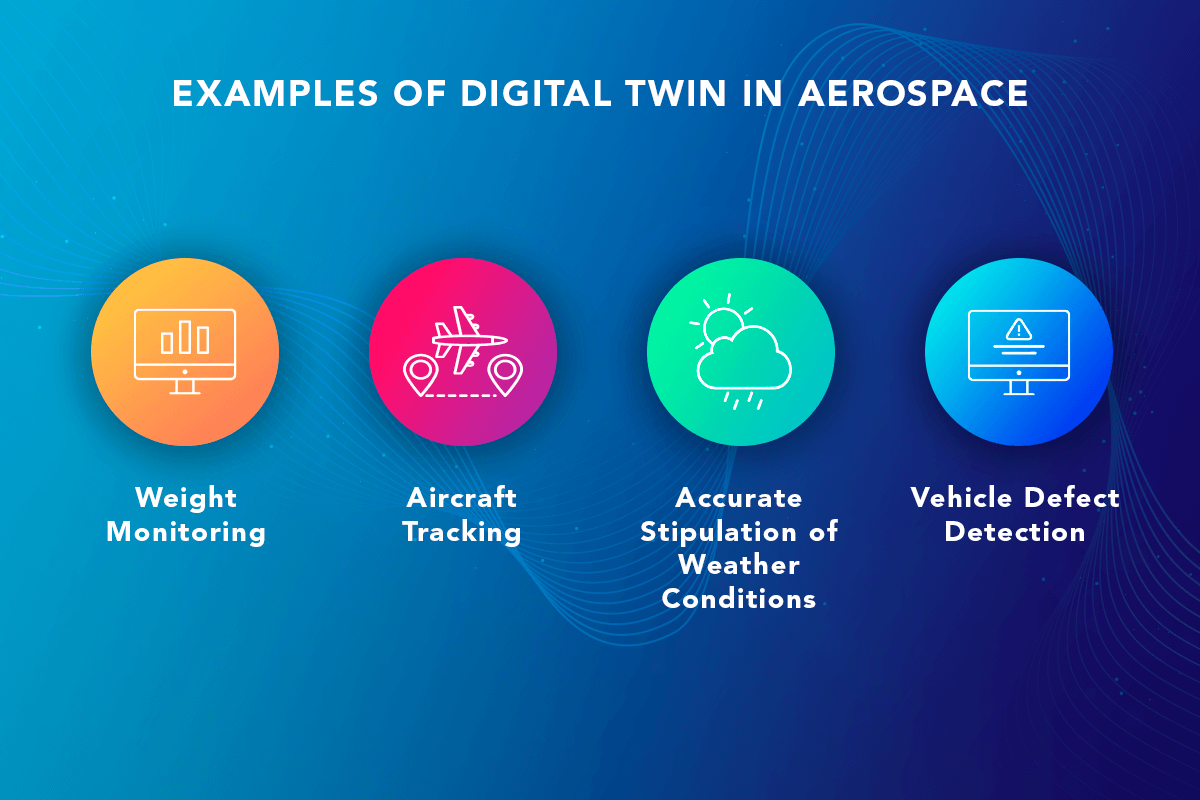

Applications of Digital Twin in Automotive & Aerospace

Applications of Digital Twin are widely embraced in the automotive and aerospace industries. Digital Twins have found use not only in vehicle engineering and design customization but are also widely used for the maintenance of large transport and aircraft. Weight monitoring, aircraft tracking, accurate stipulation of weather conditions, and vehicle defect detection are the most prominent examples of Digital Twin applications in aerospace.

According to the Business Wire survey report, 75% of air force executives employ digital twin technology in their business.

“In the automotive and aircraft sectors, they [Digital Twins] are becoming essential tools for optimizing entire manufacturing value chains and innovating new products.” Deloitte

Digital Twin for Transport Maintenance

With a digital replica of a transport unit, be it a truck, ship, or airplane, complex management of assets becomes highly automated as the digital twin systems constantly monitor vehicles, reducing manual examination down to zero. Using real-time monitoring and predictive analytics allows defects to be detected earlier and asset downtime to be significantly reduced. For instance, a Dutch air transport company KLM claims that due to predictive analytics, it has reduced its minimum equipment list defects, delays, and cancellations by 50%.

Digital Twin for Weight Monitoring

The Digital Twins technology allows logistics companies to optimize the transport load. For example, due to the weight restrictions for cargo airplanes, transport companies often underperform and carry less cargo for fear of endangering aircraft safety as it is highly difficult or sometimes even impossible to accurately estimate how much weight can be carried without posing risks. However, the use of transport twinning and flight simulation employed in Twin Weight Monitoring allows us to assess the exact cargo weight in real-time and thus avoid underperformance.

Challenge Advisory conducted tests on weight load optimization with Digital Twin revealing that by applying digital simulations for aircraft, the total load weight can be increased by 23% and that the standard weight limits imposed on flight operations tend to be far off from reality.

Digital Twin for Conditions Stipulation

The use of Digital Twins is rapidly changing the way companies develop and design their transport parks. Applying virtual replication of physical assets parts and simulation of how they behave when in use helps air transport companies to enhance quality control, the condition of the transport units, and their overall safety. Moreover, the digital twin technology can simulate the operation of their transport assets in various scenarios and environmental conditions.

Read more about XR applications in the automotive industry.

Digital Twin Use Case: Boeing

The world’s largest aerospace company Boeing uses a Digital Twin solution to develop its commercial and military airplanes aimed at improving their quality and safety.

“We’re moving to model-based engineering, digitizing our entire engineering and development system upfront, including down into our supply chain and connecting that with the production system and how we service and support to create value for our customers,” said Boeing CEO Dennis Muilenburg. “That digital life cycle – think of it as a digital twin of our airplanes – will unleash incredible value in the future.”

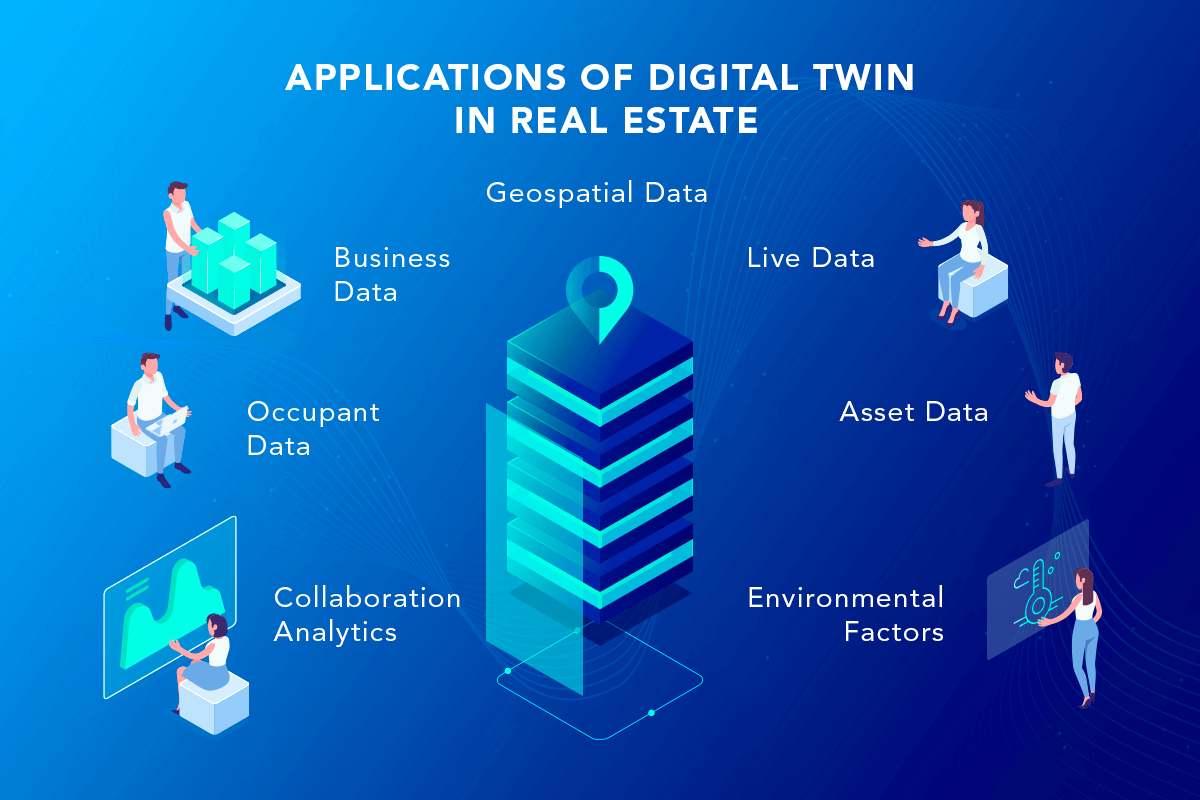

Applications of Digital Twin in Real Estate

Central management and maintenance of buildings is another application of Digital Twins. The real estate industry applies the trend of digital twinning in many ways, benefitting all stakeholders involved: building owners, architects, and contractors. Applications of Digital Twin enhance operational processes, optimize customer experience, and deliver benefits across the whole building lifecycle.

“The digital twin expands as it incorporates each new simulation and use case, slowly building up a complete view of the entire building across its lifecycle.” Deloitte

Digital Twin for Building Maintenance

Digital Twin enables greater visibility of building usage. The twinning technology can monitor the usage of the Heating, Ventilation, and Air Conditioning (HVAC), as well as lighting, by optimizing it and thereby reducing operational costs. Moreover, Twin Building Maintenance allows us to detect problems early, predict when something will fail, and suggest fixing measures.

Digital Twin for Space Optimization

The virtual model of a building allows us to evaluate space capacity and smartly design it, making it more functional and convenient for occupants. This application is especially relevant for workspaces where space allocation is vital. Twin Space Optimization allows us to determine the optimal number of workplaces and to locate them more conveniently for employees. Moreover, the Digital Twin’s ability to simulate various scenarios allows for identifying and designing emergency evacuation routes easily.

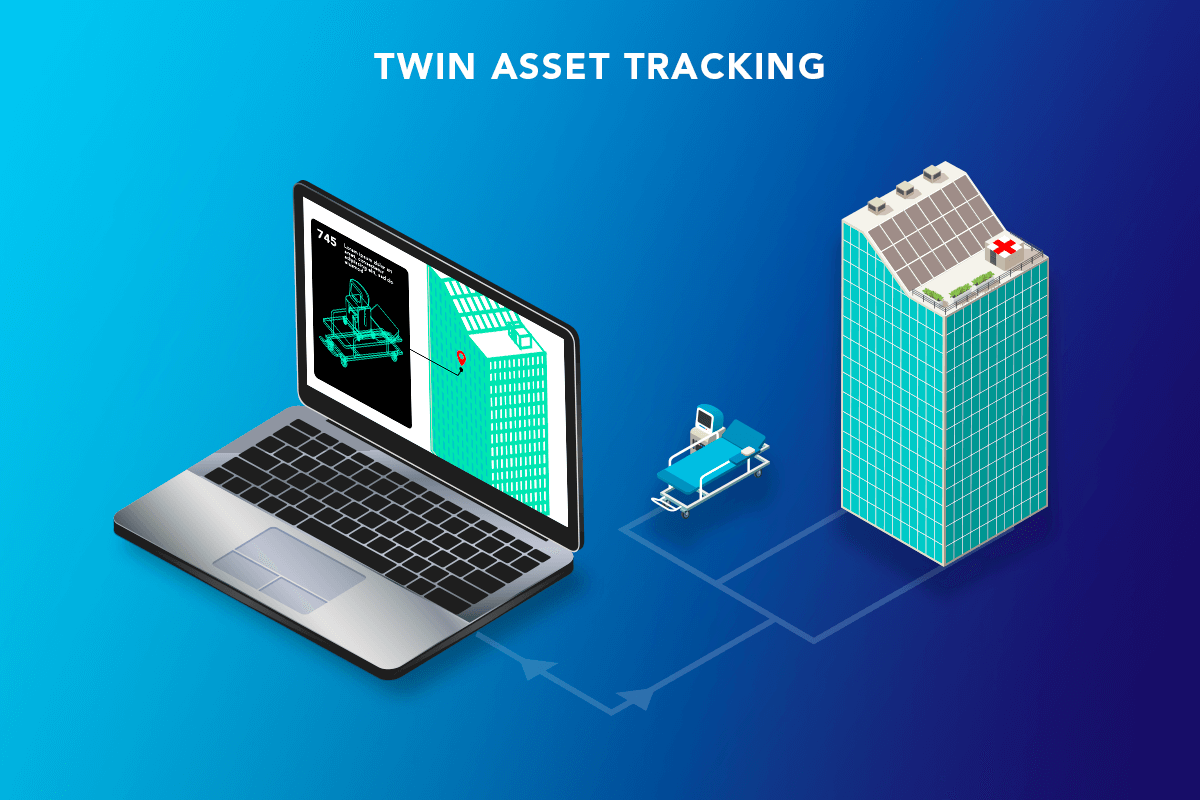

Digital Twin for Asset Tracking

It is very difficult to overview all equipment and find it promptly when needed in complex organizations with large numbers of offices, such as hospitals, factories, and ports. For instance, in an emergency, a digital twin of a hospital can help the hospital staff locate the needed equipment instrument promptly. What makes it possible is the IoT sensors embedded in all equipment that constantly transmits data to the Digital Twin system, thus revealing the current location of assets.

Digital Twin Use Case: Softengi

Softengi has developed a digital twin for Kalima Systems, a French company that produces embedded blockchain technology dedicated to the Industrial Internet of Things (I-IoT).

The Twin visualizes buildings, updating all relevant information in real time. Softengi mobile applications can read BIM files, visualizing them in a smartphone, thus allowing users to interact with these objects in real time. With digital twin technology, users can virtually walk through the digital twin building and interact with its environment.

Applications of Digital Twin in Utilities

The utility industry constantly looks for ways to enhance operational processes, decrease unplanned outrages, and keep track of market conditions.

“As we see, digital Twin is a widespread trend especially across the utility industry, as it allows power companies to optimize transient costs, enhance plant efficiency and asset performances.”

Ilya Gandzeichuk, Chief Technology Officer at Softengi

A set of applications of Digital Twins allows to model and track the state of a plant, thereby transforming the way utility companies operate. According to Accenture, more than 46% of the utility executives surveyed said they are using digital twins to improve operational efficiency.

Digital Twin for Remote Assistance

To provide better customer service and reduce maintenance costs, utility executives implement Twin Remote Assistance. With this application of Digital Twin, assets such as wind turbines, solar panels, boilers, pumps, compressors, etc., can be remotely monitored, and in case of a problem, required support can be provided distantly.

Digital Twin for Asset Visualization

If a company wants to present a new complex utility product at an exhibition, it does not need to transport it to a faraway location but uses an accurate digital model that does require any transportation or installation. Moreover, as an innovative trend, digital visualization is more appealing to customers, showing that the company is highly digitized and modernized.

Digital Twin for Asset Performance Management

Twin Asset Performance Management provides utility operators with enhanced visibility across plant assets. Due to the constant transmission of industrial data on power generation and renewable assets, executives accurately monitor plant performance, easily evaluating asset health, process efficiency, and equipment reliability. Furthermore, predictive diagnostics allows a digital twin to forecast potential faults and asset failures, thus reducing unplanned downtime.

Read more about XR technology in Utilities.

Digital Twin Use Case: Softengi

Softengi has developed a digital twin for a German company, namely a detailed 3D model of deep drilling equipment in Mixed Reality for remote training, monitoring, and maintenance based on CAD sketches. Softengi digital twins are highly accurate and adapted to mobile devices, tablets, and HoloLens. Moreover, due to Mixed Reality technology, Softengi digital twins are fully interactive, so users can manipulate and view them from every angle.

Final Word

Applications of Digital Twin have found use in most industries, transforming how businesses operate. With IoT sensors, XR capabilities, and AI-powered analytics, Digital Twin technology can preempt asset maintenance needs, reduce operational costs and asset downtime, and enhance overall business efficiency. Furthermore, Digital Twin allows testing “what-if” scenarios against business objectives enabling the most accurate decisions possible.