Oil & Gas producing and refining companies always try to minimize production costs and become sustainable. These costs are associated with equipment downtime, long decision-making, maintaining high industrial safety, and employees’ health level. Due to the lack of complete and correct information about the state of production assets and human resources involved in business processes, management decisions are often made incorrectly or with serious delay.

The task of reducing costs in many industries, including Oil & Gas industry, is successfully solved with the help of the Internet of Things (IoT).

With IoT devices, it is possible to control production levels, equipment performance, and personnel at enterprises and fields.

Top IoT in Oil & Gas Use Cases 2022

Implementation of IoT solutions reduces the cost of equipment operations and the risk of accidents. For example, before the appearance of compact smart sensors, maintenance and repair specialists rarely predicted the failure of equipment. They understood that there was a failure only when they saw the actual problem, which led to the significant time spent on the procurement (waiting for the delivery of spare parts), disruption of numerous business processes, as well as a significant reduction in production efficiency. Today using IoT capabilities, oil & gas companies can predict and prevent failures, and this is just one of the benefits of IoT for oil & gas.

Thousands of parameters obtained in real-time allow personnel to fully control technological processes, predict equipment failure, and minimize downtime. In this article, we will try to understand how IoT technologies improve the efficiency of Oil & Gas production. We will talk about the most popular IoT use scenarios in Oil & Gas, the benefits of IoT solutions for Oil & Gas, sensor-based tanks and pipes monitoring, IoT-powered Digital Twins, and utilization of sensors, RFID, GPS, and QR codes, below.

IoT for Hydraulic Fracturing

Hydraulic fracturing is an expensive and risky operation. Oilmen are constantly looking for methods that will simplify the task and increase the efficiency of this type of intervention. Today it is effective to install a network of sensors around the well that measure the surface inclination.

By comparing the information from the sensors before, during, and after the fracturing activity, it is possible to understand the direction in which the fracture has formed. The advantage of the method is that there is no need to deliver any physical objects to the well and to stop the work for the time of measurements.

Implementation of IoT in Hydraulic Fracturing

To monitor the slope, an array of sensors is placed on the surface around the well, and data from them are transferred to a single information system that determines the direction of the formed fracture by analyzing changing indicators of sensors during hydraulic fracturing. The obtained results can also be used for planning future activities.

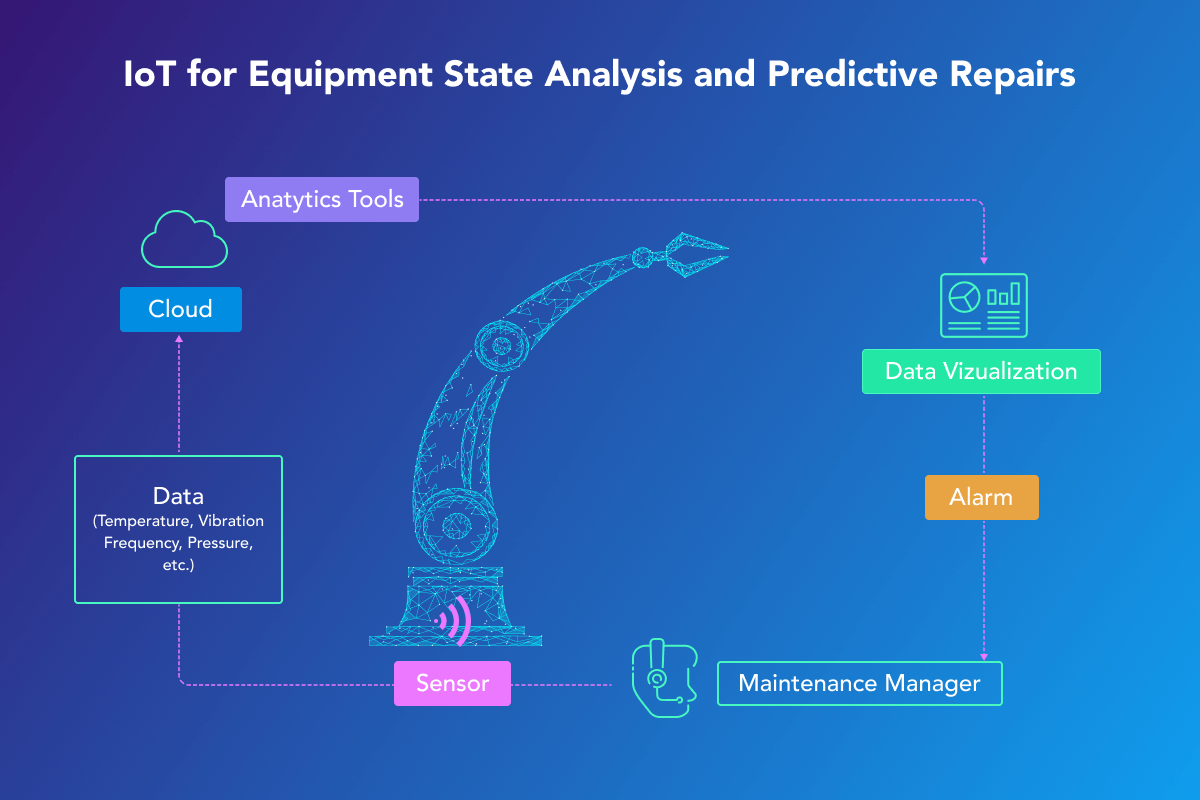

IoT for Equipment State Analysis and Predictive Repairs

In the Oil & Gas industry, incorrect forecasting and planning of repairs are costly. For example, many fields use turbines; each bearing costs more than a million dollars and can be supplied for several months. Stopping a turbine because one part is worn out may result in the entire field being de-energized.

Accordingly, there are two ways to reduce the downtime of wells. The first, appropriate spare parts are stored in the warehouse, “freezing” several million dollars for an indefinite period. Second, the turbine should be equipped with IoT sensors that allow real-time monitoring of the turbine vibrations. This helps to track bearing wear at an early stage and order replacement parts on time. Thus, the implementation of IoT in equipment state analysis and predictive repairs has obvious benefits.

Asset Tracking Oil & Gas

During the construction or repair of a drilling rig in warehouses and production facilities, spare parts and other movable property are often lost. Simple GPS sensors track the location of expensive equipment and spare parts – an inexpensive way to control their movement, storage, and use.

Implementation of IoT in the Accounting of Equipment Movement

IoT-solution based on such sensors allows personnel to collect data about valuable equipment in a single system quickly. Thus, the company minimizes the probability of loss, reduces logistics costs, and minimizes the probability of theft.

There is a possibility to use RFID, QR codes, or GPS trackers interchangeably to provide the most effective asset tracking for oil & gas. IoT-powered asset tracking is gaining popularity in many business sectors, but in the oil & gas industry, it will be the most cost-effective.

Energy-Efficient Production

The process of Oil & Gas production is becoming more and more energy-intensive, so monitoring inefficient energy consumption provides many opportunities to reduce the cost of Oil & Gas production.

Today, with the help of IoT sensors, it is possible to monitor what parameters affect energy consumption, how much consumption deviates from the plan, the “flow rate” trend compared to previous periods, etc.

The main principle of the IoT analytical system operation is constant qualitative monitoring and analysis of how the equipment consumes electricity. The system analyzes hundreds of parameters in real-time mode, comparing them with the optimal ones. If some equipment consumes too much electricity, its operation mode is corrected. The IoT system also allows personnel to regulate the consumption per hour and control the specific consumption in the main technological processes.

IoT for PPE & Employee Health Monitoring

The work of Oil & Gas employees is associated with serious health risks. The system of medical examinations and inspections before the shift is designed to minimize the negative consequences but does not allow tracking the state of employees during work.

Remote monitoring of human health indicators (temperature, pulse, pressure) using portable IoT devices is the best way to solve this problem. IoT will help to understand that workers are in good condition and there is no overheat.

Wearable ECG monitoring devices, tonometers with data transfer options, smart bracelets, and sensors on clothing allow personnel to collect data on basic parameters of human health and its location. Besides, gas sensors on clothing and production floors provide monitoring of environmental parameters, which are important for preventing intoxication.

For example, if the gas or other parameters deviate from the norm, the system alerts the manager with a signal on a smartwatch, PC, tablet, or smartphone. Alarm signals can also be transmitted to equipment with a siren or alarm lights.

Smart PPE solutions have been on the market for several years already, and now they are gaining popularity. Using sensors, it is possible to track if the employee is wearing PPE or if he/she is close to some dangerous object.

RFID, GPS, QR Codes for Asset Tracking in Oil & Gas

Sensors, RFID, GPS, QR codes in the Oil & Gas industry are needed for measuring process parameters such as fluid production volume, fluid flow rate, temperature, component composition, pressure in oil and oil products transportation systems, engine speed, power consumption, and many others. The devices control environmental parameters, pollution, and movement of objects.

IoT solutions allow personnel to improve industrial safety at hazardous facilities significantly. Built-in sensors in the helmet or work clothes collect data about the employee’s location, availability of personal protective equipment, and admissions to the facility. IoT sensors can signal an employee’s entry into a hazardous area, high blood pressure or heartbeat, or immobility over an extended period. Smart devices automatically report all non-typical states of equipment and personnel to the control console.

A network of IoT sensors collects and analyzes all technological indicators of production processes, which allows personnel to manage a load of equipment in real time. Knowing the current state of the equipment, it is possible to conduct its predictive maintenance, which reduces the costs associated with an unexpected shutdown of the processes.

Information in the maintenance and repair systems of Oil & gas companies is often entered manually with significant delays and errors. Connecting maintenance and repair systems to the IoT network will provide complete and up-to-date information on the status of equipment. In turn, this increases the ability to plan and manage repairs, as well as increases the economic effect by reducing downtime and the number of unscheduled repairs.

Oil & Gas production and refining are very energy-intensive processes, so precise control of electricity, heat, steam, and water consumption can reduce the total cost of processes. IoT monitors in real-time the technological parameters that influence consumption, compares them with the optimal ones, and compares the data for the current period with the previous ones, thus allowing personnel to optimize consumption and reduce non-productive losses.

Integration of IoT with electricity metering systems and systems for calculating energy balances significantly improves the accuracy of consumption forecasting, as well as identifies energy-inefficient production processes.

IoT Tanks & Pipes Monitoring

The oil storage tanks monitoring system allows monitoring of the tank filling process with oil. All necessary information and diagnostic data are collected and sent to the central control point. The accurate monitoring system allows not only to determine the level of oil in the tanks but also to monitor the temperature and make various preliminary calculations.

The oil storage tanks monitoring system performs two main functions: local tank management and remote state monitoring.

Most oil, fuel, or chemical storage tanks are located in hazardous areas and require continuous monitoring of pressure, fluid level, control valve position, and temperature. To maintain the safety of the personnel, a special system is used, which collects and transmits data in real time.

Oil & Gas pipelines are made of steel or plastic pipes with an internal diameter of about 4-48″. Most oil pipelines are located in the ground at 1-2m depth. Crude oil contains some wax, which gradually settles on the inner side of the pipes. Therefore, it is necessary to periodically check the state of the pipelines with the help of special sensors to detect chips, cracks, dents, consequences of corrosion, and other mechanical damages.

The pipeline monitoring system allows monitoring of such parameters as temperature, pressure, flow rate, and vibration in an oil pipeline that extends over hundreds of miles. All information is transmitted to a central control point in real-time mode.

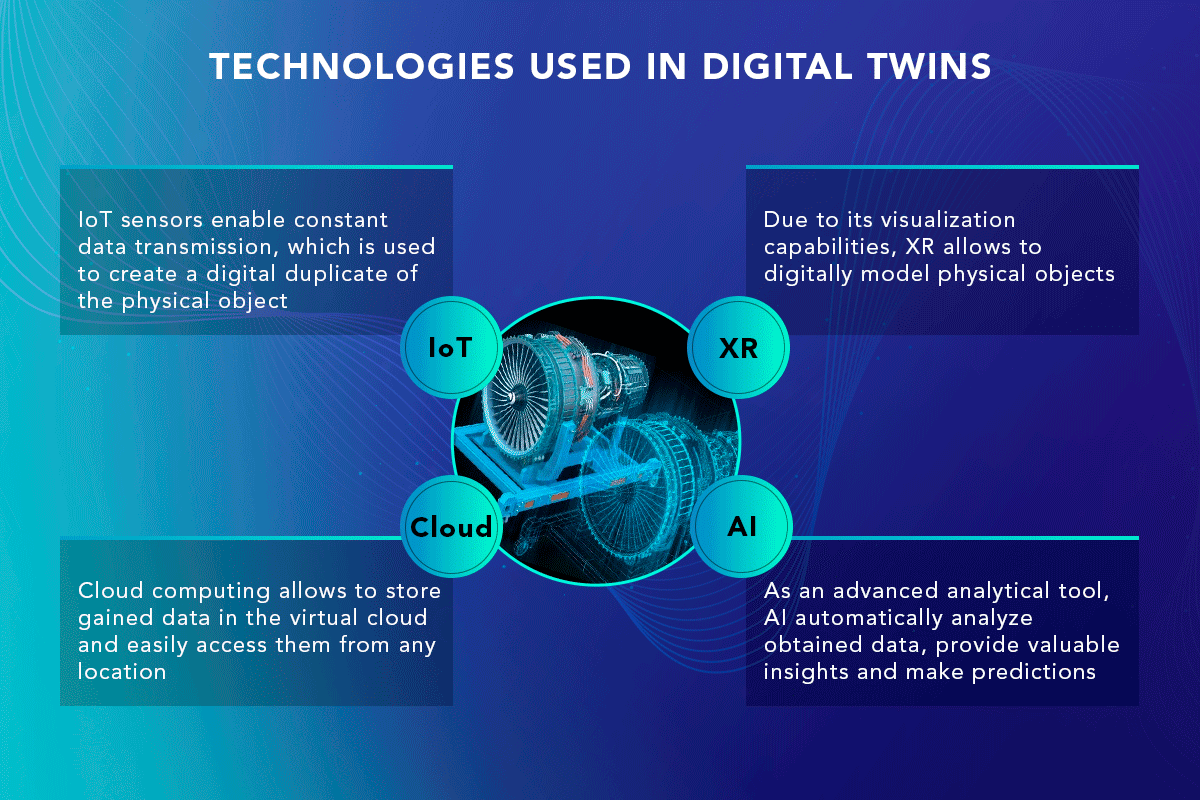

Digital Twins IoT

The technology of virtualization of objects and the creation of digital replicas of assets, buildings, and processes has significantly improved in recent years. The Oil & Gas industry has been using digital twins for more than 25 years for the exploration, development, and operation of fields – geological and hydrodynamic models of deposits, wells, pipelines, and other objects. The main task is to update the data in these models constantly. That is why IoT digital twins are gaining popularity.

Smart devices and IoT networks, in integration with modeling systems, help to bring virtual models as close as possible to real physical states, filling them with actual data directly measured at the object without human involvement. This allows personnel to monitor changes in the state of the objects constantly.

Digital twins make it possible to understand how emergency systems should work in case of fire, pipe bursting, and other emergencies at fields and refineries. Real data on the storage capacity, operation of emergency equipment, and location of personnel, obtained with the help of IoT technology, will make it easy to calculate the territory of possible spills of oil and commercial products, depending on the terrain, weather conditions, etc. Such information helps to quickly develop plans for the evacuation of employees and liquidation of consequences.

IF YOU WANT TO KNOW MORE, DOWNLOAD OUR FREE WHITE PAPER

Benefits of IoT Solutions for Oil & Gas

The main purpose of IoT is to solve the difficult task of rapid mass technological data collection from many production facilities of the Oil & Gas company. Smart devices organize the prompt and safe transfer, long-term storage, and correct visualization of technical data for all services and departments.

Smart sensors collect, exchange, analyze data, and in case of emergency, transmit warning signals to the control center. Configurable algorithms analyze technical data and determine the relationships between them. This allows to control of the operation of the equipment and machinery, forecast its technological state, and organize safe operation, as well as remotely monitor the personnel’s well-being and promptly respond to its critical changes.

An important advantage of IoT is the elimination of human factors in quick decision-making during the typical functioning of technological processes. If technological processes significantly deviate from the specified values, IoT transmits information to the specialists responsible for process management and offers the following solutions:

- Data exchange management: personnel gets full visual access to Oil & Gas production, transportation, and processing data;

- Detailed reporting: personnel uses real-time data to meet safety, environmental and regulatory requirements;

- Forecast analytics: personnel receives notifications before maintenance and operational changes.

- Virtual reality: IoT expands emergency awareness, speeds up training, and provides detailed work instructions and remote recommendations;

- Source of reliable data: personnel gets a clear picture of equipment in operation, whether it is used centrally or locally;

- Employee communication: it is possible to use location-sensitive monitoring to ensure employee effectiveness and safety.

Conclusion

Almost every Oil & Gas company has the potential to use the Internet of Things for its benefit. It is relatively easy to gather data on how the equipment works, how much energy it spends, and where this or that asset is located. It is also possible to get the fullest information about oil& gas employees subject to various risks. Using smart PPE and physiological parameters monitoring with wearables, oil & gas companies can ensure everything is fine with all the workers.