As buyers and producers of goods are approaching the winter holiday season, both expect exquisite gifts and a safe environment. Assuring the quality of goods and keeping employees safe is the task that developers of computer vision manufacturing are best at.

Computer Vision for Quality Control

Enterprises value machine vision manufacturing solutions because they can promptly find inaccuracies in commodities during their production. In this way, enterprises can safeguard products’ quality. And, very importantly, CV solutions are capable of identifying the cause of inaccuracies. By checking and solving the flaws of production machines on a plant, companies can plan more volumes for each machine. This means that CV solutions can enhance sustainability and raise the productivity of enterprises without raising the number of machines.

And this is not the limit. If earlier CV QA solutions were only trained to control certain labels, for example, labels on pans, then new solutions based on deep learning can learn to control different package types, with different labels, and for different products. This means that they can be installed on different product lines or in different locations and companies. Strategically rolling out one multi-product CV QA solution across your enterprises can significantly cut the monitoring and quality assurance expenses of your business.

The overall route for digitalization, AI, and fighting lockdown consequences in this industry are the reasons why CV solutions are becoming more popular with investors.

Computer vision is part of AI that uses CNN (convolutional neural networks) to process images and videos as pixels and trains computers to “understand” them. In this way, industrious machines can identify objects and react to what they “see.” For these purposes, CV developers can use such tools as TensorFlow, PyTorch, OpenCV, CUDA, Keras, and MATLAB. A usual CV solution for manufacturing represents a platform that can use cameras, GPUs (graphical processing units), VPUs (vision processing units for AI), the IT ecosystems of enterprises, or the cloud to control conveyors.

Here are a few fascinating use cases of CV solutions being applied to manufacturing enterprises and what tasks they successfully solve.

Computer Vision for Package Inspection

Every large enterprise that produces packaged goods needs some type of CV solution for package inspection. But some industries need this control dramatically.

For example, retail and pharmaceutical enterprises endeavor to have 0.00% inaccuracy while packaging their goods. They need a precise number of items, accurate label marks, clear production, and expiration dates, distinctly printed product information, and absolute integrity of the packaging. And CV solutions can meet 100% of their expectations. Successful CV QA solutions for packaging on any respectable enterprise should look like this.

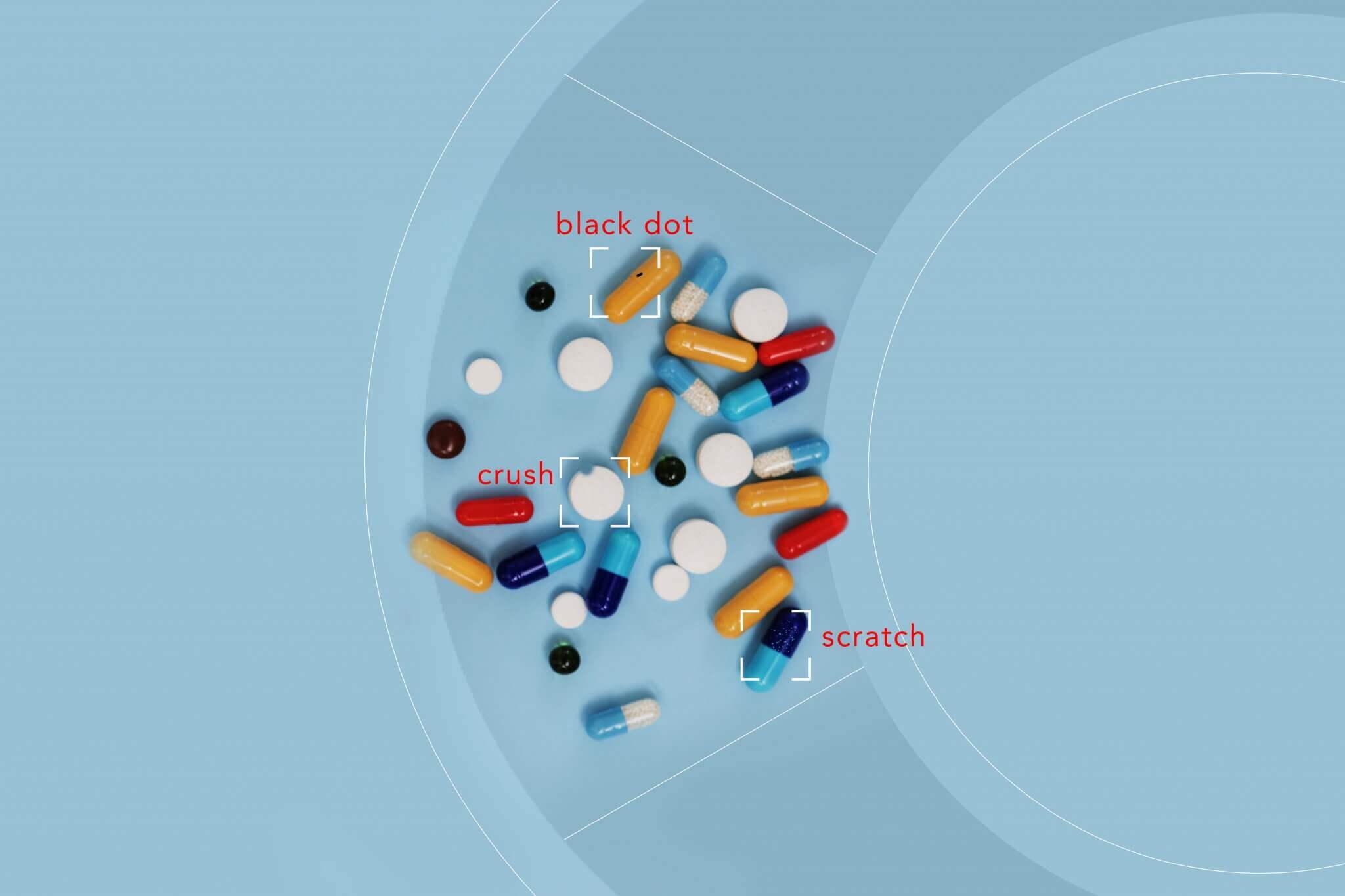

Computer Vision for Coating Inspection

There are quite a large number of industries that are very particular about coating inspection. Pharma companies take good care about the coating of their tablets, oblongs, soft gel capsules, and plug-in capsules. After all, this is the first thing that the buyers see after unpacking the pill before taking it. That is why they are vigorously applying CV for coating control. To scan and analyze a huge amount of tiny objects, CV developers have to take a tremendous number of pictures of each pill in a flow while rotating them. If a pill does not meet the criteria, the software rejects the pill. The usual throughput of CV solutions can equal hundreds of thousands of pills per hour.

Now, CV developers can offer a sole device for scanning desperate sorts of pills of different sizes and chemical compositions of the coating, no matter big elongated capsules or small rounded tablets. Not so long ago, each machine could only scan a certain type of pill.

Each sort of pill has a set of criteria to pass. Though, there is an admissive variability of checkpoints. Developers do not reject a pill because it has a slightly different color if it is admissible.

Usually, machines check:

- Dimensions of pills;

- Consistency of coating;

- Color of coating.

In this way, pharma companies secure their reputation and offer high-quality medicine to their buyers. However, pharmaceutical companies are not the only ones to use sophisticated CV for coating control.

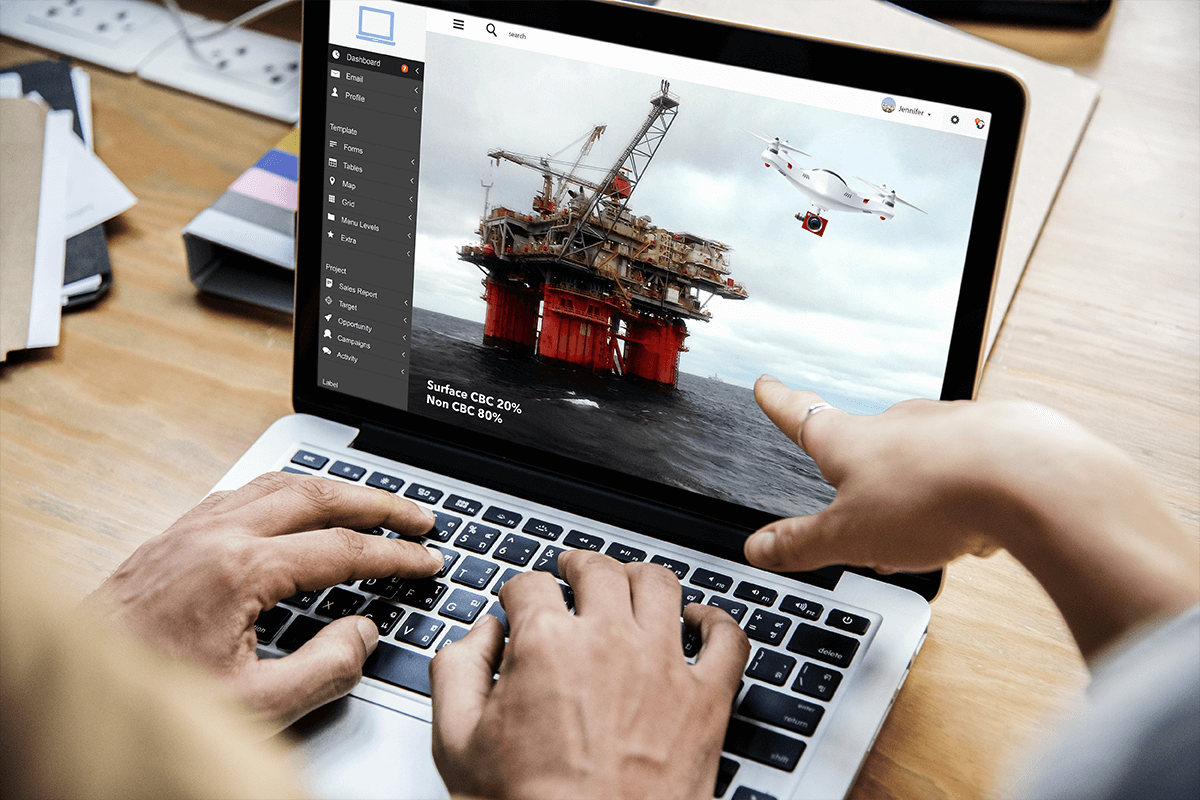

For example, oil and gas companies are happy to have special CV devices for battling corrosion on their marine and offshore structures. Usually, the companies apply protective coatings on their property. And they do Coating Breakdown and Corrosion (CBC) evaluation tests to learn about the condition of the surfaces. Even so, the owners still have a problem. They cannot see or collect sufficient data from the surfaces because the marine and offshore structures have rather large dimensions with many inaccessible areas. At the same time, coating breakdown and corrosion can cause dramatic and expensive consequences for them.

Here, developers offer CV solutions mounted on drones or other robotic devices to better collect information. These robots don’t have to be humanoid like the ones Elon Musk is building and will not need years to launch. They are fast and small enough to do the job and carry CV hardware and software. They can promptly identify the exact location of damages, classify the diverse types of damages, evaluate the percent of damage, and show the owners the results on their devices. The company can actually see the exact rust /“health” picture of their properties in a reasonable time.

Computer Vision for Detecting Defects

Finding flaws is a vital stage in safeguarding product quality while manufacturing. The timely identification and fighting of flaws are essential to cut operational and quality-related costs. Companies usually apply CV QA devices to find visual inaccuracies in products, such as metal tools, that do not require ultrasonic or X-ray capacities.

To find inaccuracies in products, CV devices first get the images of the products, detect defects, classify them, and reject defective products. CV devices can find inaccuracies fast, in different orientations, with complex backgrounds, find occluded inaccuracies, and tiny inaccuracies.

Companies order them because they are efficient, work fast, in a non-destructive way, and have low cost.

Inventory Management

Developers offer manufacturers installing CV cameras on their inventory for a number of reasons. First, these cameras can automatically count the number of inventory in stock and define if any supplies are low in the production process that the inventory is servicing. In this way, CV contributes to serving the production based on current demand.

Also, together with IoT devices installed on the inventory units, CV cameras can benefit the predictive maintenance of the inventory. The company can actually see the state of the inventory while reading the data from the IoT devices, such as cracks, fatigue, scratches, or holes. And predictive analytics systems can use extra visual data from cameras to make more precise predictions.

Computer Vision for Improving Worker Safety

As the COVID-19 restrictions are easing and employees are returning back to their workplaces, the question still remains, how safe are they now at their workplaces, and how can an enterprise be ready for changes in health protection requirements?

The Guardian cytes Hans Kluge, the WHO’s regional director for Europe, as saying:

“Vaccines are doing what was promised: preventing severe forms of the disease, and especially mortality. But they are our most powerful asset only if used alongside preventive measures.”

Let’s remember the story of the town of Cargill in Alberta, Canada, where the workers of a meat-packing plant issued a strike notice to the employer because of their concerns over COVID-19 safety measures in the workplace.

CV developers have always been offering CV cameras for monitoring safety measures at workplaces. Usual cameras presuppose manual monitoring of the stream that is error-prone. On the other hand, CV cameras are capable of redboxing employees without masks, employees who do not keep a 1.5m-2m distance, and employees who show alleged signs of COVID-19 infection. They can be installed at the enterprises and alert or notify management, and transmit information to dashboards for decision-making. This step can contribute to health safety at the workplace and to smoothing the relations between the blue colors and the companies.

Moreover, CV solutions for health safety control can retrain for new or altered safety criteria and be used for health safety control as long as the pandemic lasts.

Besides, the AI development community is now complaining that not so much data has been collected over the pandemic time compared to eventual possibilities to do so. With these images, the developers can train CNNs. And if the developers had had more diverse and disparate data from workplaces, the new solutions could have developed faster. This means that if you order CV cameras for health safety in workplaces for your enterprise, you are contributing to the development of AI in this field.

CV developers offer solutions for various quality assurance cases during production and for health safety control, especially during holiday seasons and challenging times.