New technologies are becoming increasingly applied in our daily reality. Today’s humans can no longer imagine their lives without computers, the Global Wide Web, smartphones, and numerous “smart” gadgets. Mobile apps, payment terminals, touchpads, and many other smart things have become an important part of everyday life.

Nevertheless, there are areas where advanced technology is difficult to go in, as specialists often prefer to work in an old-fashioned way. This includes, first and foremost, the energy and the utility sector. There are several reasons why these segments do not tend to implement advanced technologies. First, the players in these segments prefer to use traditional methods in their work. Secondly, the transition to new technologies requires professional employee training. Thirdly, the introduction of any technological innovations requires significant investments.

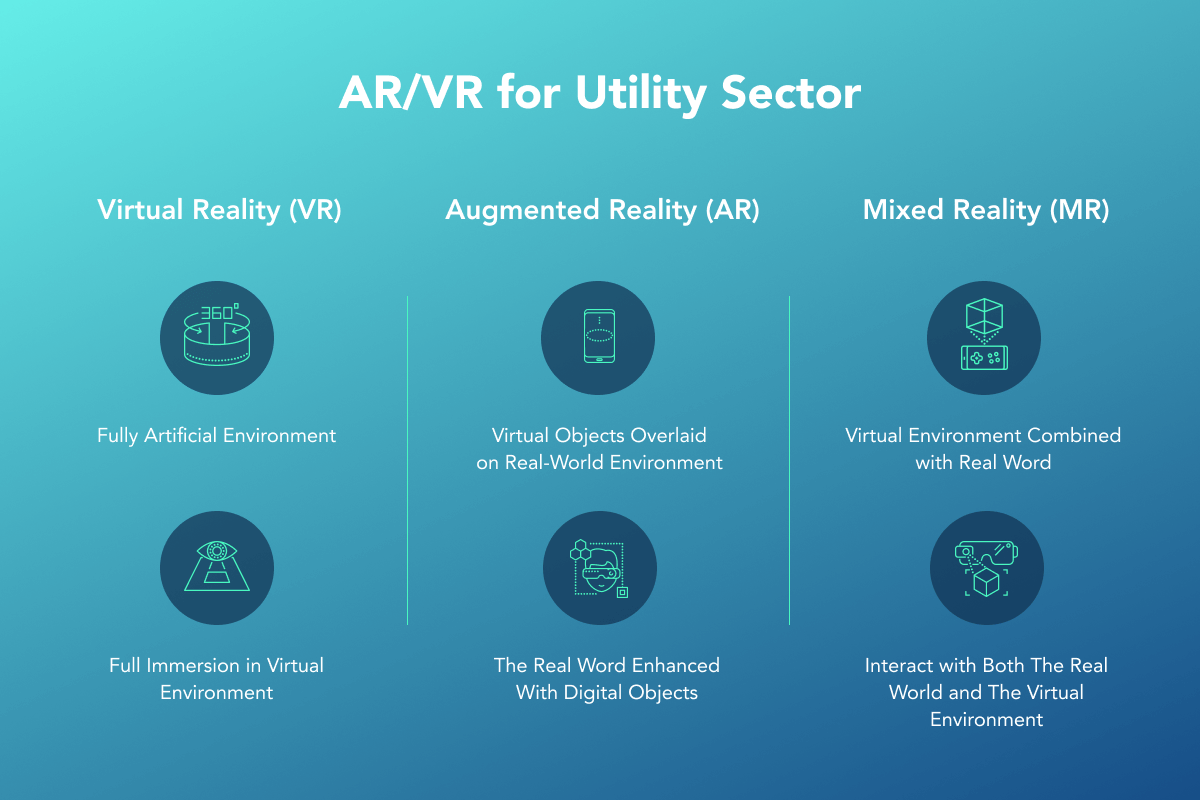

However, as we can see already, advanced technologies can significantly improve the operational efficiency of energy and utility companies, thereby improving the quality of customer service. The use of virtual (VR) and augmented reality (AR) in the utility sector reduces operating expenses, improves safety, and expands the list of services provided.

Application of Virtual (VR) and Augmented Reality (AR) in the Utility

First, AR and VR can simplify maintenance and repair processes in the utility sector. Besides, new technologies can create an efficient and safe work environment for utility employees. AR for Utility is gradually being implemented by various companies worldwide. The size of the AR/VR market is constantly increasing, making it clear that these solutions are very applicable as more industrial players implement them. They just have not become widespread yet. Today, companies that implement AR/VR solutions in their operations create the basis for a successful future. This also positively affects technology development because the more AR/VR solutions are used, the more capabilities and features they provide.

So how can efficient and safe work be achieved in the utility sector using AR/VR? There are many ways of AR/VR utilization in different industries. Below are just some of the virtual and augmented reality applications that can be used in the utility.

Staff Training with AR/VR

The utility sector is severely understaffed. Lack of technical skills, specialized education, and needed experience are the main challenges facing hiring managers in the utility sector. And this is where advanced technology can come to the rescue.

AR and VR can be very useful and effective for training new employees. With these technologies, workers can get the necessary professional knowledge and learn how to work without exposing their lives to various risks, just as pilots and drivers are trained in simulators. Technicians can virtually learn how to deal with the various problems that await them in the workplace.

Various situations can be simulated with advanced computer software based on AR and VR technology. However, Virtual Reality plays a major role in employee training than Augmented Reality. For instance, with VR headsets, users are placed in computer-generated reality, which simulates various incidents they might encounter on duty. Thus, employees can efficiently learn how to respond to emergencies.

Using AR and VR in the utility industry can help organizations to increase their efficiency as workers are going to be better prepared and handle any unforeseen situation more quickly. This will not only help utility companies save time and operating costs, as well as increase efficiency, but also save lives in the event of an emergency.

The use of AR and VR technologies improves awareness, competence, and cooperation among utility employees, which, as a result, is very beneficial for the microclimate in the team.

Inventory Management Using AR/VR

AR and VR technologies are successfully applied for managing various material and technical assets, for instance, equipment and inventory.

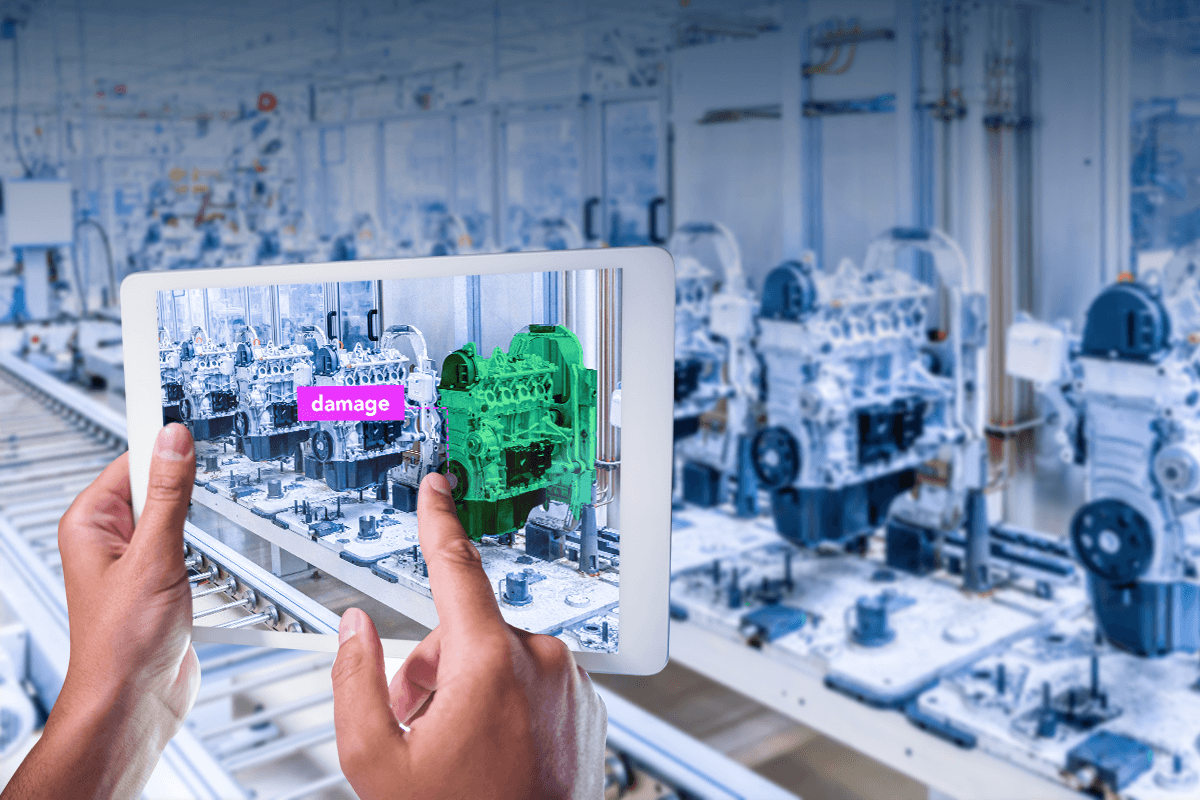

Augmented Reality technologies can also overlay digital information on real-world reality. For example, a photo or video can be overlayed on a real object via a smartphone or tablet. Such techniques are useful in case of power outages or equipment damage. A technician can take a snapshot of the damaged equipment via the AR app. The app then processes data to determine and analyze the exact location and extent of the damage, sending valuable insights to the company. Additionally, a technician on-site can request the parts needed to make a repair and advice from more experienced professionals. As a result, AR helps to save valuable time, efficiently make repairs, and restore power or water quickly.

The use of AR and VR technologies is especially relevant if there is no qualified technician at the scene of an emergency. In such cases, an augmented reality-enabled mobile device can transmit complete data on faults and damage to an appropriate expert or a company specialist who can promptly send a repair team. First, this can be useful for quick response to accidents and their prevention.

Besides, with the help of AR technology, technicians can detect any structural damage during scheduled inspections. Using the overlay technology adopted in Augmented Reality, it is possible to accurately determine the degree of wear of specific equipment parts and organize their repair or replacement accordingly. The world’s major energy companies are already using similar methods.

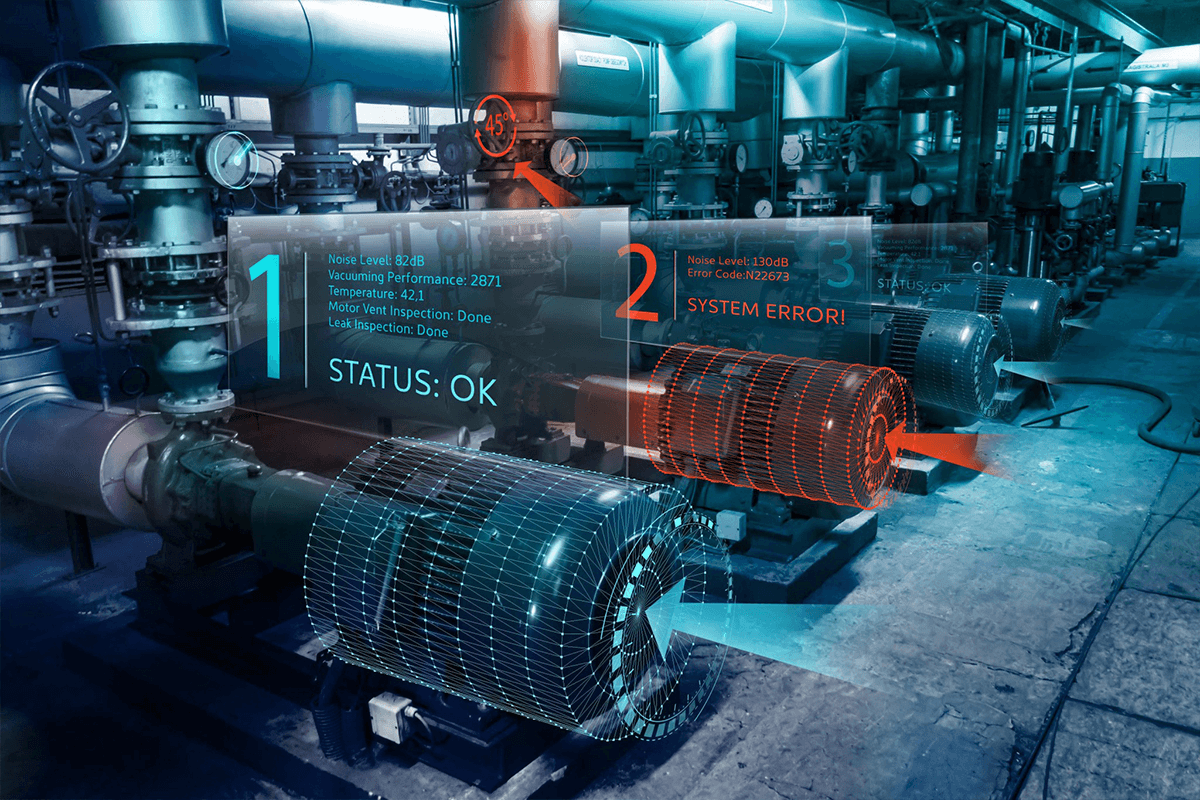

Data Generation and Visualization Using AR/VR

Multiple data sources are used for AR systems. This allows utility workers and consumers to more fully analyze and more effectively cope with emerging problems. One such information source is a consumer’s mobile device with video or photo recording capabilities. Consumers can notify a utility company of an accident sending it a video recording or a photo. The data obtained will help professionals in the preliminary assessment of the extent and location of the damage, as well as in planning repair work.

Moreover, managers can plan procedures before technicians are informed of the emergency. The team can immediately develop effective methods to control the occurred situation. It helps save precious time because emergencies are often dangerous. Besides, users can inform utility companies of various emergencies via social media.

Another source of information can be unmanned aerial vehicles (UAVs). Such devices generate various visual, infrared, GPS information, and other data. The obtained information can be used to further process, producing actionable solutions. As more and more devices support Augmented and Virtual Reality, they continuously advance, generating more detailed information and valuable insights that, as a result, lead to further technological improvement.

Digital Twins

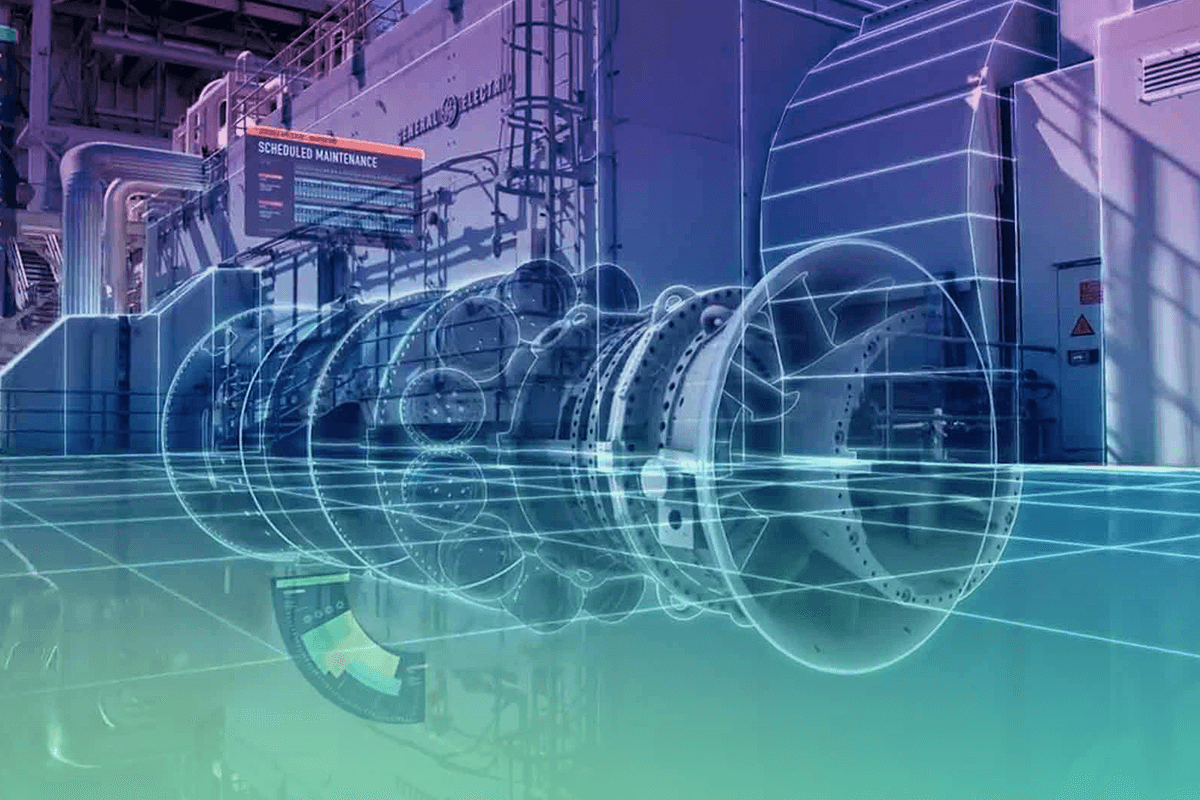

Digital twins are virtual copies of real objects that are used to test the performance and efficiency of an element or system. With Digital Twins, engineers now test new sensors and products more quickly and easily, maintaining them in time. This technology is one of Industry 4.0’s fastest-growing concepts. The growth of the IoT and Cloud technology significantly impacts the digital twin market.

According to Gartner, digital twins are used in 13% of organizations implementing IoT projects, while 62% are either already implementing the technology or plan to do so. According to the MarketsandMarkets report, the digital twin market will grow from $3.8 billion in 2019 to $48.2 billion by 2026. Digital twins are already widely used in the utility sector, but they are also highly useful for manufacturers.

Read more about Digital Twins.

IF YOU WANT TO KNOW MORE, DOWNLOAD OUR FREE WHITE PAPER

Advantages of Using Digital Twins: Operational Assessment of Risks and Repairing Time

With a digital twin, companies can control the quality of an architecture system before it is actually developed. As a digital twin is a copy of the planned system, technicians can spot any failures in the process before the system starts to work in real time.

Due to digital twins, testing intensity can be increased 10-fold, and the labor involved in structural design processes can be reduced by 85%. Overall, engineers can re-engineer the system by generating unexpected scenarios, learning how the system reacts, and creating mitigation strategies.

In such a way, digital twins allow us to assess risks better and promptly develop new utility systems and more reliable production lines.

Predictive Maintenance

As the digital twin sensors generate big data in real time, businesses can analyze internal statistics and identify any system failures in advance. This allows companies to move towards predictive maintenance while increasing production line efficiency and reducing operating costs.

Real-Time Remote Monitoring

If an employee works with a complex system, a manual check of any system´s element constantly is impossible. However, a Digital Twin makes it possible, as it can be accessed anywhere, allowing users to monitor and control system performance remotely.

Improved Collaboration

The automation of processes and 24/7 access to system information improves a company’s productivity and efficiency. So in a team, developers can concentrate more attention on the creation of new elements instead of wasting time on controlling and rechecking those already launched.

Improving the Financial Decision-Making Process

Material and labor costs can be specified in a virtual model. This allows companies to make faster and more efficient financial decisions: whether the cost is calculated correctly, what might affect it, and so on.

Moreover, with Digital Twins, financial losses because of lost productivity can be avoided. For example, previously, business owners had to stop all work processes to test new warehouse modules. Today, it all happens virtually, and the effectiveness of settings is easy to double-check.

What Should Be Considered Before Implementing Digital Twins

First of all, you need to update your security protocols. Gartner estimates that, by 2023, 75% of digital twins for OEM products connected to the IoT will use at least five different types of integration endpoints. The volume of data collected from multiple endpoints is enormous, and each is potentially vulnerable.

Therefore, before implementing Digital Twin technology, companies must review and update their security protocols. It’s worth paying particular attention to:

- Data encryption;

- Access rights, including clearly defining user roles;

- Least privilege principles;

- Remediation of known device vulnerabilities;

- Regular security audits.

Companies should also ensure their staff has the necessary skills and tools to handle digital twin models. Nevertheless, the number of digital twin use cases in utility is constantly increasing. Digital twins have a great impact on all industries. They simplify the work of employees. Any investments for further digital twin implementation are justified because, right now, it is one of the leading technologies that drive our world. It’s hard to underestimate the benefits of this technology.

Challenges Arising when Using AR and VR in the Utility

One of the major problematic issues is the slow adoption of advanced technologies by major players in the sector. In order to put them into practice, the appropriate infrastructure must be in place: availability of mobile devices, access to Wi-Fi and power sources, and compliance with safety precautions.

Manufacturers of devices used in AR and VR applications have to provide convenient and uncomplicated items. The equipment should have a simple user interface so that technicians can easily understand how it works. The shape and size of the device are also important. They should not be bulky and heavy, especially drones. Devices should meet the safety standards set by the companies.

AR and VR transform the utility sector, making it more efficient. Companies must not only apply advanced technology to their daily operations but also learn how to develop appropriate technical and financial strategies, as well as collaborate with experienced professionals. All this will help improve the quality of customer service, increase profitability, and be competitive in today´s market.

Read about how AR enhances utilities.

Conclusion

Smart technologies allow companies to reduce costs, increase efficiency, and optimize maintenance. In particular, Digital Twins with AR/VR solutions can give any company more opportunities than any others.

The world is continuously moving forward and businesses that don’t develop with it will not be in demand in the future. Today, as never before, it is very important to digitally optimize company business. As we see from global business experience most of the companies that implemented AR/VR solutions got a great boost for their business. AR, VR, Digital Twins, and other related technologies are very necessary for the success in today’s volatile market.