The population of the Earth has already exceeded the mark of 7.3 billion people and will not stop there. By 2050, it is expected that 9.7 billion people will live on the planet. In this scenario, the first role comes out of the nutrition issue because to feed such a huge population, it is needed to multiply the production of food. Farmers and engineers are already working on this task and plan to achieve it by developing and building “smart” farms.

Serious changes in precision agriculture (management concept based on observing and responding to variability in crops) will occur on the threshold of the fourth industrial revolution. Cyber-physical systems, IoT, and cloud computing will be systematically introduced in it.

Technological innovations can be applied to almost all sides of precision agriculture. The technology being introduced can be divided into three main categories, which will be the basis of “smart” farming – autonomous robots and various IoT software & hardware solutions. We will talk about smart farming, drones, harvest logistics management, agriculture machinery tracking, soil moisture sensors for agriculture, and smart warehouses/greenhouses below.

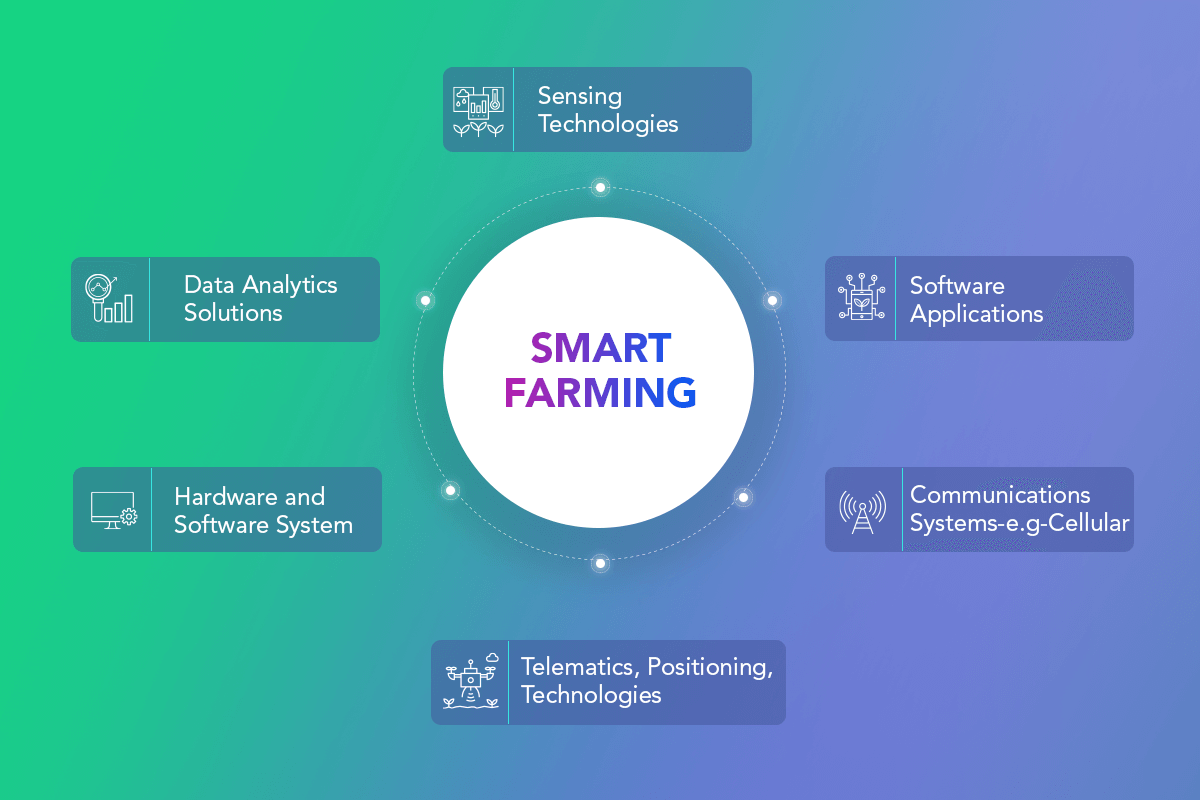

What is Smart Farming?

Smart Farming is a new concept in the field of agricultural land management that involves the use of modern technologies. Smart Farming allows for increasing the quantity and quality of products without increasing the amount of human labor.

The farmer can increase the production level by introducing new technologies in precision agriculture. It is necessary to develop farms with automated control systems, the parameters of which vary depending on the microclimate and the state of plants on farms. Only in such farms the quality of products can be improved to “extra” class and ensure stable growth of profits.

For this purpose, it is necessary to create and introduce competitive technologies, produce complexes of robotic machines for farms, develop modern protection systems, introduce a complex of IoT agriculture sensors to control the physiological condition of plants, etc.

Drones in Agriculture

The use of drones in agriculture is one of the most promising applications of this technology. Drones in agriculture can be effectively used for planning and control of stages of agricultural production, as well as for chemical treatment of crops and other plants. At the same time, the main advantage of the implementation of UAVs is economic feasibility.

Drones in agriculture allow you to get relevant and effective information when you need it. Moreover, accumulated over a long period of time information allows you to analyze the processes in the dynamics.

Drones in agriculture can collect information about planting needed for the accurate use of pesticides and herbicides. This allows farmers to save on chemical use as well as save the environment.

The UAV allows you to create a map base with the exact coordinates of all objects, allowing you to create a further visual analysis of objects with a resolution of up to a few centimeters per pixel. This map base may apply vector layers (fields, infrastructure, roads). It enables you to calculate exact areas, distances, resource requirements, etc. It is comfortable to determine the objective area of arable land, hayfields, pastures, and sowing.

Aerial photography using UAV is more detailed than a space image. Imagery resolution is available in centimeters per point due to flight heights from 100 to 600 meters above the ground surface. Besides, the UAVs allow for taking images even in cloudy, inaccessible conditions to satellites.

It is possible to receive images even during the flight, and it is possible to correct the flight in real time if the customer needs it. It provides significant savings in research costs compared to all other research options: ground survey, satellite photography, and manned aviation.

The drones in agriculture can not only collect information but are also used directly for spraying fields and other plantings, including spot planting.

Harvest Logistics Management

The automation of logistics business processes is becoming more popular. In today’s conditions, precision agriculture needs timely deliveries and cargo transportation. IoT software can solve the following issues:

- Calculate routes taking into account the model of the transport network and the admission of the car to certain areas of the city/country;

- Define the logistic way of transport (location);

- Manage vector maps. The software may contain editable electronic maps with address databases linked to them;

- Measure onboard parameters (speed, amount of fuel consumed, mileage, car idle time, etc.);

- Identify and prevent the issues with cargo getting lost. IoT can inform about the loss and can adjust the delivery plan.

The application of harvest logistics management allows transmitting information over GSM, GPRS, and 5G channels. With the help of the IoT, it is possible to control and manage transport effectively, as well as get maximum economic benefits:

- Reduce the need to increase the number of transport;

- Minimize vehicle maintenance costs and lubricants by optimizing routes and reducing unproductive mileage of vehicles;

- Optimize the work based on real mileage data;

- Reduce losses associated with repairs and vehicle downtime.

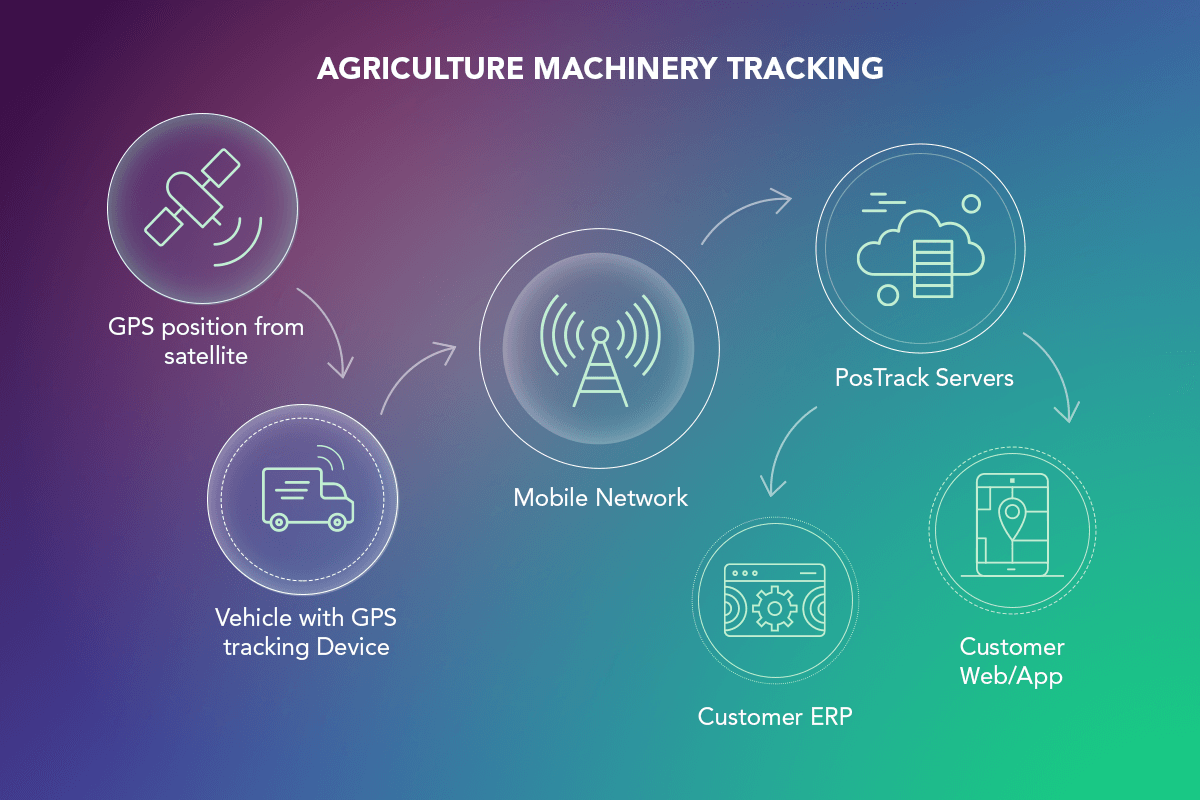

Agriculture Machinery Tracking

Harvesting is a seasonal job that does not require the constant availability of drivers. They are needed only during the harvest period – depending on the plant, this period begins in June and ends in November. Sometimes the field owners do not even have their equipment – they rent it when needed. This approach allows field owners to avoid expenses on equipment purchase and maintenance.

During the harvesting period, the calculation with hired harvesters, as a rule, is based on the area of the field they harvested. Naturally, drivers always try to overestimate the size of the area they have cultivated, and it is not always possible to prove otherwise. There are also frequent cases of collusion between harvesters and agrarians, who rent combines for harvest.

The satellite tracking system in such situations shows unambiguously what exactly the area was processed by this or that combine harvester in a day, which allows to avoid inaccuracies in payment for its work and to observe all agreements.

A satellite tracking system can help:

- Find out if the equipment is working according to the plan;

- Control the safety of equipment, and in case of theft, quickly return it;

- Determine how much fuel each tractor spends per shift;

- Find out exactly where the equipment is and where it has been all day;

- Find out if the fields are being processed correctly;

- Calculate the exact area worked by each tractor per shift;

- Know the exact position of the machine at present and at any time in the past;

- Promptly come to the aid in case of a sudden machine breakdown.

Smart Warehouses/Greenhouses

In its dynamic development, any enterprise that operates warehouse space once faces the need to optimize warehouse processes.

Someone can take the path of expanding staff and premises while working around the clock. However, all these changes will still lead to a sharp increase in costs and reduce distribution efficiency.

A promising way to increase the efficiency of the warehouse is its full or partial automation following the precision agriculture needs. Maximum automated warehouse operations are achieved through the use of modern technologies, which make the warehouse more intelligent.

Smart Warehouse is a complex of technologies, which allows retailers and logistics operators to solve warehouse logistics tasks optimally and efficiently for themselves. In this set of processes, objects are inextricably linked with automation tools.

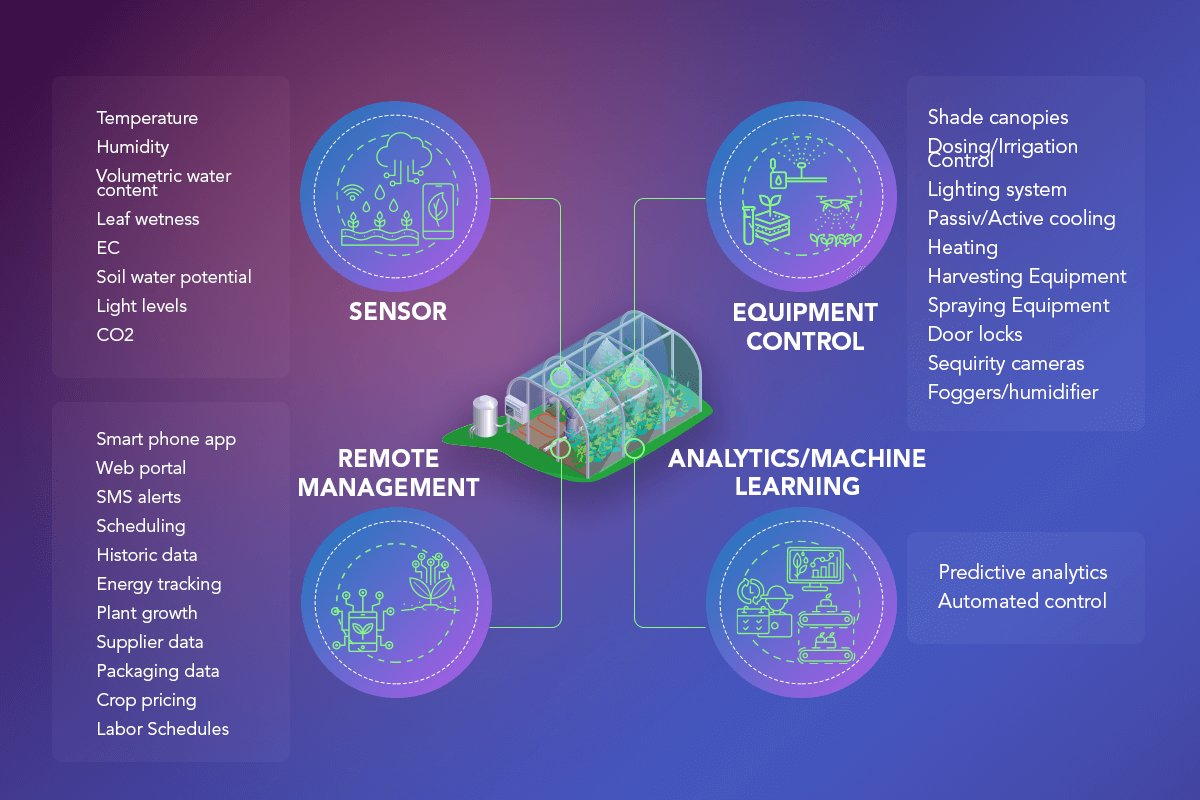

At the same time, the Smart Greenhouse is a fully automated structure designed to minimize the use of manual labor. This agricultural facility includes microcontrollers, IoT agriculture sensors, and management systems.

Often, smart greenhouses work in synchronization with other technological solutions, such as automatic irrigation technologies and HVAC systems. IoT agriculture sensors capture plant growth, irrigation, and lighting data and send it to a local or cloud server. The administrator web console allows farmers to customize system settings and integrate them with other solutions.

Smart greenhouses can be divided into those that use hydroponics (cultivation of crops without soil) and conventional cultivation of crops in the ground. Ground cultivation solutions prevail in the market.

The key technologies are:

- LED projectors for plant growth;

- Soil moisture sensors for agriculture;

- Irrigation systems;

- Valves and pumps;

- Monitoring systems;

- Control systems.

Smart Greenhouses Advantages: Monitoring of the Equipment, Air Conditioning Systems, and Humidity Maintenance

Besides maintaining an optimal temperature, it is necessary to ensure the preservation of equipment and effective operation of air conditioning systems, humidity maintenance, etc. Soil moisture sensors for agriculture help to monitor the humidity level. The earlier the farmer discovers a temperature drop or equipment failure, the more likely the property and plants will be preserved. Remote monitoring systems send updates in real-time so that employees could respond quickly to threats.

Monitoring the Situation

If any condition exceeds the preset range, the device or system can immediately warn the responsible employees by phone, e-mail, or SMS. Notifications of emergencies usually inform the farmers about the following:

- A temperature drop;

- Poor ventilation;

- High carbon dioxide levels;

- Changes in humidity;

- Equipment failure;

- Water leakage.

Prevention of Diseases During the Vegetation Period

During the growing season, systems in smart greenhouses can control various environmental conditions. For example, the humidity level is monitored by soil moisture sensors for agriculture. Both wired and wireless IoT agriculture sensors are used for controlling. Maintaining the set parameters of temperature, humidity level, lighting, and air circulation is crucial to prevent mold and disease and maximize plant yield.

Conclusion

The main objective of including autonomous robotic systems in precision agriculture is to reduce dependence on manual labor and increase product efficiency, profitability, and quality. In contrast to their predecessors, agricultural producers of the future will be engaged in data analysis and business planning. They will need employees to repair and maintain equipment.

As already noted, for all agricultural AI systems, reliable support by IoT agriculture sensors is vital. The key to true smart farming is the ability of all machines and IoT agriculture sensors to communicate with people and with each other, even if they work autonomously.