The Internet of Things rolled onto the Agriculture industry as the 2nd wave of the Green Revolution with accurate real-time data and expanded to the fields, machinery, and warehouses. IoT hauled the main trophy for the agriculture businesses:

- Decrease the costs;

- Increase the yields.

Clip From the History of AI and AgTech

It’s been decades since developer companies offered the sensors for the fields, machinery, and warehouses to Agriculture businesses. But the sensors could only store information that they gathered in their inbound memory to be later collected by the farmers. With the coming of the Internet of Things in Agriculture, developers can now offer the business owners real-time accurate data from the sensors available on their devices.

Tip 1: Available connectivity in your region

In the past, Agriculture businesses in detached regions could not use IoT devices because of the lack of connectivity. By now, with the development of technology, almost every remote strip of land has been covered by satellite connectivity, cellular network, or other types of connection. And implementation of AI and IoT systems for Agriculture has become much easier.

Tip 2: Any smart device a farmer buys now can be trained through data ingestion and become smarter

If a farmer or holding decides in favor of IoT for Agriculture, in time the IoT knowledge base will expand and even small IoT devices that they purchased will be apt to upgrade significantly.

Technology controlled by AI could see an increase in efficiency over time. AI and neural network solutions can be trained through data ingestion and become smarter, contextualized, and more aware, – says Datascienceweekly.

What makes farmers ponder over and over about the smart AgTech?

In this article, you will learn about:

- Centralized IoT asset tracking: Machinery at the focus;

- IoT is out there in the fields: streamlining Scouting;

- Learn how to make use of the Smart Warehouses.

Centralized IoT Asset Tracking: Machinery at the Focus

IoT solutions company can develop a mobile IoT asset tracking application that can track asset location, audit and monitor assets, and keep accurate centralized records across the Agriculture business.

Challenges of farmers:

- A manual and decentralized approach to asset management causes poorly operated assets;

- Time-consuming audits, no images, and no real-time data cause inaccurate reports and decisions.

Solutions of AI and IoT Developer Company

IoT sensors located in the machines can monitor the state of machinery and transmit information to multiple devices of the personnel. As well, GPS trackers on the machines can track the location and movement of each machine and transmit real-time data. Both can transmit data in a centralized IoT Assets tracking hub. In the hub, an individual farmer and managers of holdings can:

- Track the location and movement of all machinery;

- Keep the history of the location and movement of each machine;

- Monitor in real-time the condition of the equipment;

- Receive predictive maintenance alerts based on fuel consumption and time of operation;

- Keep the history of fixes, issues, and other statuses of the assets.

A centralized IoT Assets Tracking hub can solve a number of everyday challenges owners, managers, and drivers face, make asset management easy, and work process smooth.

IoT is Out There in the Fields: Streamlining Scouting

AI and IoT for scouting can by no means replace humans on the ground but can offer powerful assistance. That is why conventional crop scouting is becoming obsolete.

Smart Scouting – 3 Simple Steps:

- Drones collect information from the fields;

- Drones transmit data to the farmers’ tablet/smartphone/desktop with Smart Scouting App installed;

- Smart Scouting App offers a wide range of activities with the data.

What Flying Scout Drones Can Do in the Fields:

- Create diverse types of maps of the fields using sensors;

- Scan and analyze the crops for abnormalities;

- Make satellite imagery of the crops;

- Make images in the near-infrared.

Drones make images based on the Normalized Difference Vegetation Index (NDVI), as measured by a satellite remote sensor. They scale the field in colors from open soil to dense vegetation and measure regions by hectares. Afterward, drones transmit information to smartphones, tablets, or desktops in real time.

What Ground Scout Drones Can Do in the Fields:

Ground Drones have onboard 3D-device that continuously create a 3D map of the environment, tag objects with geo-tags, and do not require GPS. Farmers and Drone managers can control the Drone to:

- Light up the problem plants;

- Make a live stream of the findings;

- Make a detailed registry.

What Farmers Can Do in the Smart Scouting App:

- Get a 3D map, a close view of objects, and geo-tags;

- Get near-infrared pictures of objects and interactive GPS maps;

- Make notes and snapshots on the map;

- Work with vegetation maps and graphs;

- Create tasks for scouts for inspection;

- Work with soil productivity map and graph – to correct fertilizing plan/routine;

- Work with time/precipitation graph – identify flood;

- Work with time/temperature graph – identify temperature drop/rise;

- Share information with colleagues;

- Share information with the insurance company.

Comparing different types of graphs with imaginary from the fields and the data on the map of the field, individual farmers and managers of agricultural holdings can draw informed conclusions about what is happening in the fields and react accordingly.

Collateral Information That Smart Scouting App Can Show:

- Marketing information;

- Rain and heat history of the region;

- Crop insurance offers.

Many minor farmers just use the reduced version of the Smart Scouting App to aid their personal scouting – without phase 1 and drones.

What Minor Farmers Can Do in SSAs:

- Make snapshots and notes of the crops;

- Organize the history of the crops;

- Have alerts for fertilizing/watering the crops;

- Share the information with any interested party.

Also, they can use it as an advisory tool because AI can promptly find and tip region- or plant-specific data.

Use Case 1: A Manager Creates a Task for Scouts

If a farmer or manager notices abnormality on the map of their Smart Scouting App they:

- Touch the abnormal zone on the map;

- In a pop-up, create an inspection task for a scout: make an imaginary, describe the problem, and give the coordinates;

- Assign the tasks to a scout.

The scouts with the mobile Smart Scouting App:

- Go in the fields, find the zone using GPS;

- Collect the information there;

- Share the information via satellite or cellular connection with the farmer or manager.

Use Case 2: Sending an Incident Report to the Insurance Company for Damage Validation

If a farmer notices on the map any type of incident/accident on their fields that can qualify for insurance coverage they:

- Make before and after snapshots of the map;

- Make a snapshot of the graphs;

- Create a note;

- Send the message to the digital address of their insurance company.

Smart Scouting App is an effective assistant in scouting for individual farmers and agriculture holding and can bear the exact set of functions each company can need.

Learn How to Make Use of the Smart Warehouses

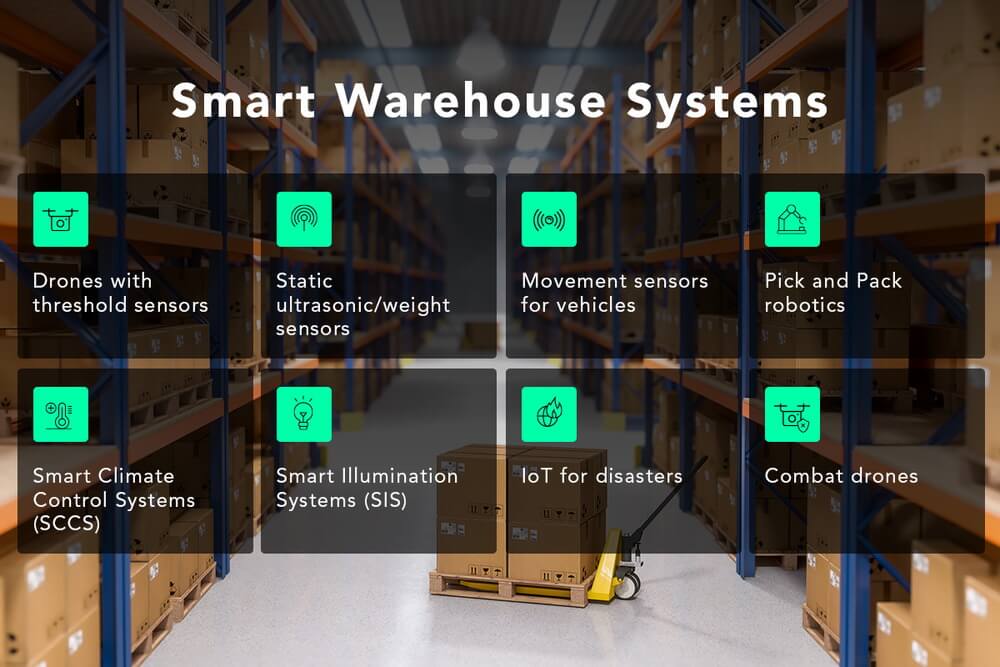

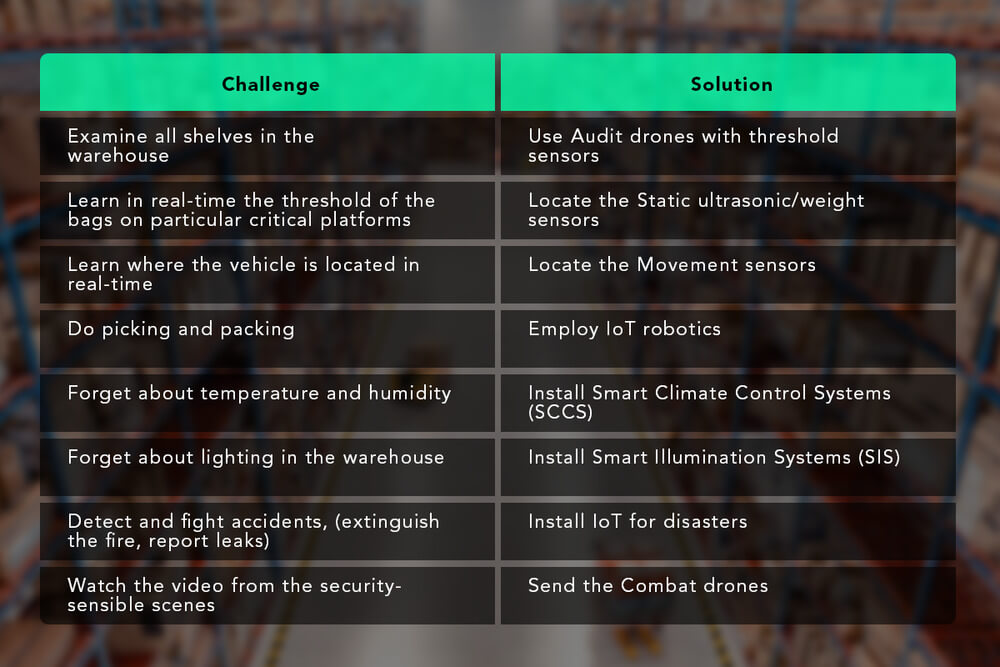

IoT devices of the Smart Warehouses Systems handle routine processes that the personnel of the warehouses perform: audit the shelves with refined products, platforms with bags, and track the movement of vehicles. IoT devices can transmit the data to apps or via secure methods to the interior Warehouse Management System (WMS) for decision-making.

Guide How-to Make Use of Devices For Smart Warehouses

Digital twins represent infrastructure assets that simulate and automate the same physical assets.

MarketAndMarkets research calculated that in 2026, the global digital twin market will equal $48.2 billion pitching from $3.1 billion in 2020.

For an AI&IoT solution to be designed, developed, and installed in a warehouse, management of the warehouse has to:

- Examine the needs of the warehouse;

- Examine the eventual AI&IoT options of the developer company;

- Share this information with the AI&IoT developer company;

- Get cascading proposition;

- Evaluate the resulting profit.

Each warehouse is different and needs a unique approach. If a company does calculations, the resulting Smart Warehouse can turn out more profitable while introducing them to a new higher level of warehouse management.

Conclusion

AI and IoT cover many phases of the life-cycle of the Agriculture businesses and are applied for Monitoring and tracking of machinery, for smart scouting with flying and ground drones, and in smart warehouses. IoT with GPS tracks machinery in the fields, drones make various types of maps for crop monitoring and insurance cases, and smart climate control in warehouses preserves the crops. All the devices can independently work and due to satellite, cellular, and other types of connectivity transmit data in very detached regions. All the IoT devices and systems can be integrated into the inner management systems of warehouses via secure methods. Each use case is unique for every company. Each company can save their money and bring their work to a new higher level with the IoT for Agriculture to produce nutrition for the growing population of the planet in a more effective way.