Would you need warehouses without retail stores? After all, goods are brought to warehouses just for the timely replenishment of store shelves. At the same time, storing surplus in warehouses nowadays is an unforgivable luxury. Businesses do everything to ensure that their goods go directly to stores rather than being stored in warehouses.

In logistics, there is even such a term as “JIT, just-in-time” which means that the goods are not stored for an excessive amount of time and are received and sent out almost immediately. This article will explain and give examples of how IoT (the Internet of Things) sensors can be used in warehouse management in the most effective way to guarantee this unattainable just-in-time approach.

Smart Warehouses for Timely Delivery

We could hardly imagine that someday cashiers in supermarkets would be wearing protective plastic face masks. These are the realities. COVID-19 doesn’t ask who is allowed and who cannot be infected.

Online shopping substituted habitual visits to the stores, but it also has its cons. Is it a familiar situation when the packer calls and says that some goods are out of stock, offering to replace them with other goods?

Therefore, the control of goods on the shelves and overall smart warehouse management would be very useful, not only for buyers but also for merchandisers. Of course, a lot will depend on the nature of goods: controlling the availability of salt is not cost-effective, but controlling the presence of boxes with fruit would be relevant. Moreover, it is also possible to control the climatic conditions in warehouses.

IoT Sensors for Warehouses for Timely Information

Here they are, IoT ultrasonic sensors. Their work is very simple and similar to the echolocation the bats use. They can measure the distance to the surface from a few centimeters to several meters with a margin of ±1 cm (depending on the model), and they are perfect for measuring the presence of goods on the shelves.

Using IoT sensors, businesses can turn simple shelves into smart shelves and receive the most accurate and relevant information about the inventory.

If a supermarket runs out of oranges, a notification is sent to the delivery service. Simple, reliable, and cost-effective. At the same time, there is no need to supply power to the sensor itself. They are autonomous, and their battery life is estimated by years. Installation is simpler than ever. Attach it to some surface from above. What about theft? Nobody needs them.

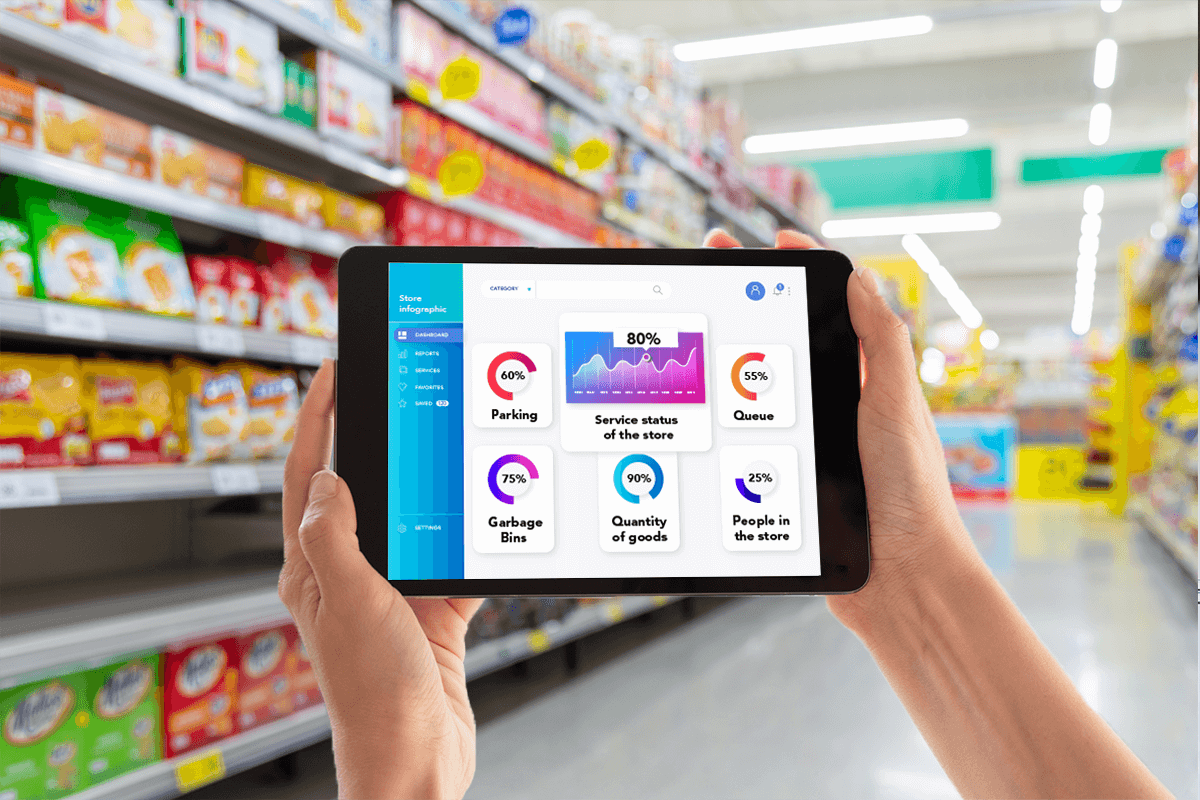

Also, these sensors can be used to count customers. The calculation will be approximate, but it is nevertheless possible to determine the busiest hours and ‘downtime’ in relative terms. Thus, it optimizes the number of staff in the store at a given time. The presence of sensors near the checkout will allow you to call another cashier on time if necessary. They can also be used in the parking lot near the store. It is especially important in the parking lots of the takeaway service. Like, I’m here, waiting for my goods. More relevant than ever!

Besides, these sensors can be installed on garbage cans, called smart bins. It is unpleasant for you to go into a store with full trash bins next to it. How do you know when it is overflowing? Information from sensors could be transmitted to a service that deals with garbage disposal. Thus, you would not have to pay to remove half-empty bins. In other words, a garbage truck would only come to take out full garbage boxes.

Smart Warehouse: Ultrasonic, Touch, Climate & Threshold Sensors, Drones

Now it is important to understand the amount and the time of goods delivery. For example, the same oranges are to the warehouse: when should they be sent to stores?

To solve this problem, you need to know how many and how quickly they are being sold out in stores today. This is where the most valuable information will be from ultrasonic sensors that are installed in stores. At the same time, you can control not only the availability of goods on the counter but also in the warehouse of the same store, like the number of boxes left.

In addition to ultrasonic sensors, touch sensors can be used. They allow you to determine the availability of goods on the shelves more accurately. Additionally, there would be valuable information on how often customers have touched the product. How often they were interested in the product but did not buy it? Perhaps the reason is that it has expired. The same information could help store security to prevent theft as well.

This is how we approached the inventory. Sensors are sensors, but visual control is indispensable here. Next, let’s talk about drones. After all, only they can fly around all the premises, never fall and hit the shelves. After that, the information analysis software, created based on Artificial Intelligence (AI), will approximately count the goods on the shelves, and the operator checks and clarifies questionable places. It is not even the accuracy itself that is important, but the fact that this can be done without the participation of the storekeeper. This is the dream of any owner!

Drones can also guard warehouses, the so-called “combat drones.” Their principle of operation is the following. They are at their base, where their batteries are recharged before the event. When the alarm sensors are triggered, they fly to the scene and transmit the video to the guards, who decide whether this is a false alarm or a real theft or fire. I don’t know about you, but the drone would scare me more at night than the security company’s arrival.

Climate Sensors for Incidents Prevention

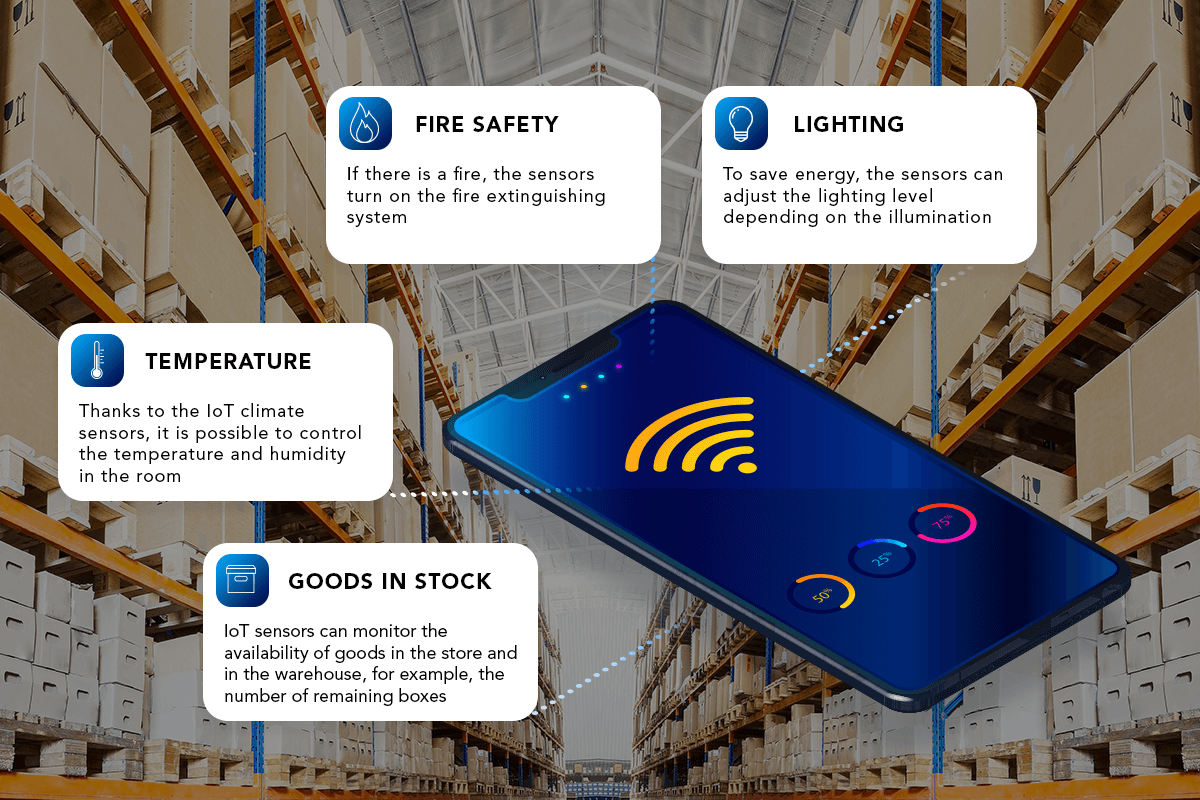

What else I would like to add is that there are IoT climate sensors and threshold sensors.

Thanks to the variety of sensors, it is possible to control the temperature and humidity in the room, as well as water leaks, fires, and other incidents. Most sensors operate autonomously for years, which allows them to be used in hard-to-reach places without supplying additional power.

Sensors can not only transmit information but also control devices. For example, the sensors turn on the fire extinguishing system if there is a fire. They can adjust the lighting level depending on the illumination to save energy.

Thus the variety of applications of IoT solutions for smart warehouse management is immense. Determining exact use cases is what is required from you!