It’s true. The Internet of Things is proving itself to be far more valuable than just a data-gathering technology. It’s literally serving to prevent major injury and fatalities on some of the most dangerous job sites in the world.

Those who work in the Oil & Gas, Energy Production, and Construction industries know full well the critical safety risks and environmental hazards they face daily on the job. Until now, avoiding incidents has been a byproduct of using appropriate Personal Protective Equipment (PPE) and a regimen of regular Best Practice and safety and awareness training. However, since human beings are involved, not everyone is as careful and diligent as they should be. And therefore, “accidents” do happen.

The good news is that advanced information technologies, such as the Internet of Things (IoT) mixed in with a little Artificial Intelligence (AI), have been brought to the table to help dramatically reduce onsite incidents with predictive warning capabilities that have never existed in the past.

IoT for Personal Protective Equipment

Imagine, if you will, all workers on a job site who might potentially be in harm’s way being outfitted with an array of wearable sensors on their person, monitoring in real-time:

- Helmets

- Vests

- Safety Belts & Harness

- Gloves

- Boots

- Goggles

In addition to all these small, unobtrusive sensors, is a Controller Unit no larger than most call phones attached to the wearer’s belt? This Controller aggregates all of these sensor inputs and wirelessly relays them to a network gateway on the job site, passing all that information to a server that analyzes and processes that information and then presents real-time status and analysis to site supervisors and managers.

In this scenario, knowing that all Personal Protective Equipment (PPE) is being worn is known instantly. If, for example, a worker takes off their helmet and sets it down, the system knows and then alerts the supervisor/foreman, who can respond appropriately.

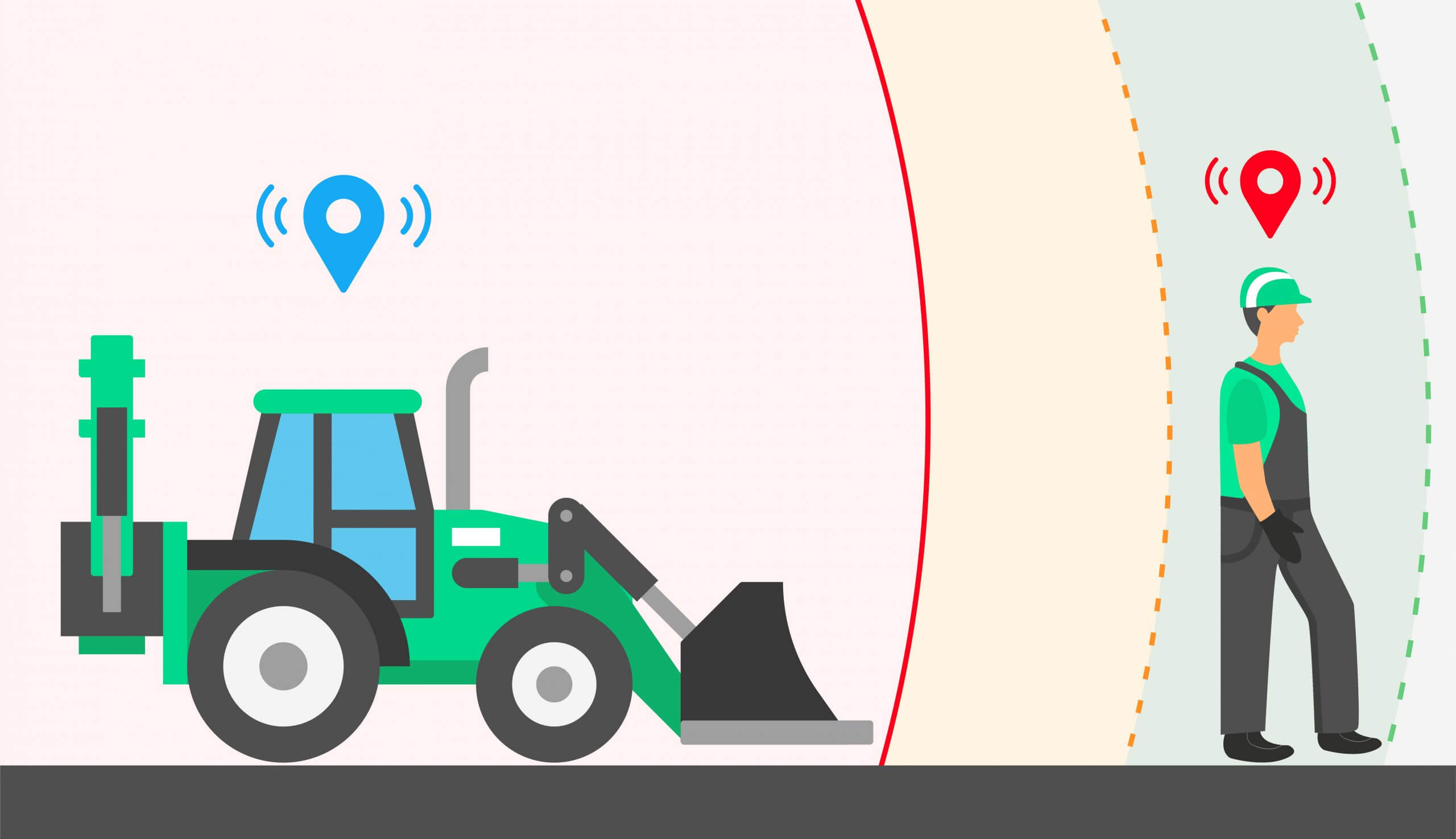

But it doesn’t end there. Now imagine this IoT system also features Zone sensors for dangerous areas where personnel is not allowed to go. Should someone inadvertently enter such a danger zone, the GPS geolocator/geofencing application sends a warning alert.

And there’s more!

How about Confined Space wearable sensors that also measure the air for dangerous gasses or sufficient levels of Oxygen? Yes, that’s part of it, too – along with measuring the worker’s heart rate and body temperature to ensure no one is getting overheated or experiencing physical distress.

AI/IoT for Collision Avoidance

How about vehicle sensors? One of the most common safety incidents on major job sites involves vehicles coming into contact with other vehicles and/or personnel. IoT can use GPS to track all personnel and vehicles, with predictive logic looking for potential collisions and sending out appropriate alarms to the drivers of those vehicles for collision avoidance.

Clearly, having this level of real-time visibility and reaction capability can potentially save many lives and prevent serious injuries – and that is its primary mission. But that’s only the beginning of the overall value proposition of this type of technology. Having such a system deployed yields many other tangible and valuable benefits to any organization using it.

Benefits of IoT-based Incident Prediction System

With an IoT-based Incident Prediction System (IPS) in place, a detailed audit trail of data is produced, which is ripe for analytics. Thus, safety compliance becomes a data-driven practice – objective, not subjective.

When there is an inevitable incident, there would now be a Forensic Audit Trail to determine exactly what happened. Who was there? What caused the incident? How can you prepare in the future to avoid similar events? Is additional training required in specific areas/gaps identified by the system?

It’s conceivable that such a system would also lower an organization’s overall risk profile, and therefore have potential ramifications on liability and insurance rates. If having a security system on your home can lower your homeowner’s insurance costs, perhaps there are similar benefits available.

Even the Human Resources department of organizations using an IPS system could enjoy new benefits. Such a system requires workers to “sign/check in” to the system at the beginning of a shift and “sign/check out” when finished for the day. That could directly be tied to Time & Attendance data. Actually, the GPS data correlated with the heart rate monitors could even let you know if someone was taking a nap while on the job!

Just imagine the “activity data” such a system could produce. Who’s working the most? Who isn’t working very much at all? Is everyone located where they are assigned and need to be?

Obviously, any system such as this is but a tool; and tools are only as good as those who use them. Without a strong “Culture of Safety” in any organization, the greatest benefits would never be enjoyed. But coupled with the proper training, having advanced tools like this in place can legitimately “up your game” to levels never previously possible.

The simple fact is that an onsite supervisor only has one set of eyes and can’t reasonably be expected to see everyone doing everything all the time on a major job site. IoT can be those eyes and ears for operational managers, alerting them in real-time to real dangers, hopefully in time to stop bad things from happening. IoT can also produce a forensic audit trail that can aid in certification of safety compliance, incident investigation, and even help with personnel management. It’s a technology whose time has come.

Conclusion

Indeed, all of this may sound like science fiction, but it’s not. In fact, this technology is currently in use by some of the largest industrial companies in the world, who were instrumental in helping pioneer it. Yes, it’s cutting-edge innovation, but it’s already been proven on the job and is in commercial production.

If you would like to learn more about IoT/AI Incident Prediction System (IPS) technology and explore whether your organization is ready for such capabilities, please contact Softengi.